- 2-15 -

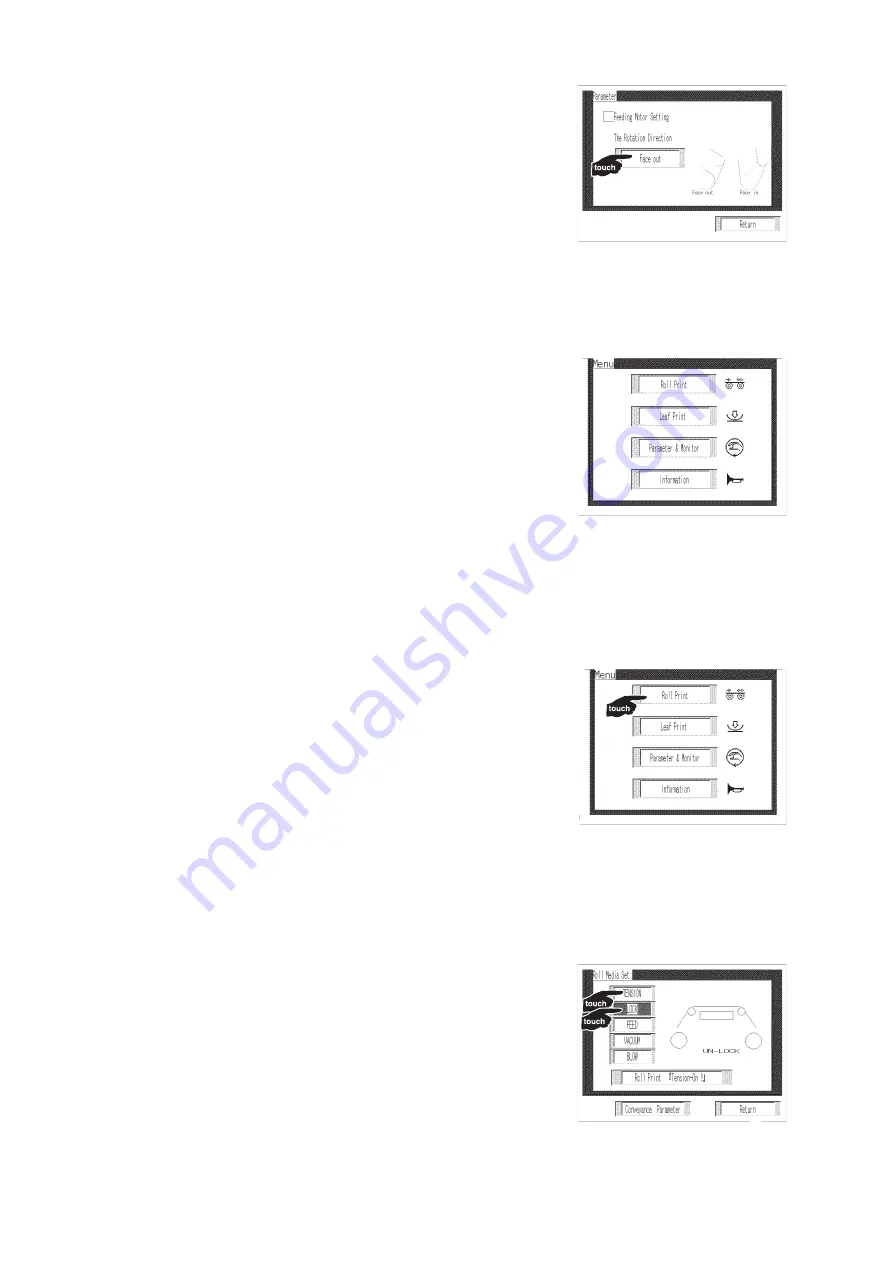

c. Touch the [The rotation direction].

Switch the [Face in] or [Face out] by touching

the panel.

d. Touch the [Return] three times.

Return to the [Menu] screen.

e. Touch the [Roll Print].

f. Touch the [TENSION] and [LOCK].

The roll media turns around.

Make sure of the turning direction.

If a wrong rotation direction is selected, start

from STEP a.

Summary of Contents for UJF-605RII

Page 22: ... xx ...

Page 82: ... 2 40 ...

Page 104: ... 3 22 ...

Page 114: ... 4 10 ...

Page 148: ... 5 34 ...

Page 162: ... A 6 ...

Page 168: ...A 12 D201670 1 10 27122007 ...

Page 169: ......

Page 170: ...Printed in Japan MIMAKI ENGINEERING Co Ltd 2007 EM FW 1 10 ...