41-621.1 HART

®

to Modbus

®

Adaptor Operating Manual

35

11.4.11

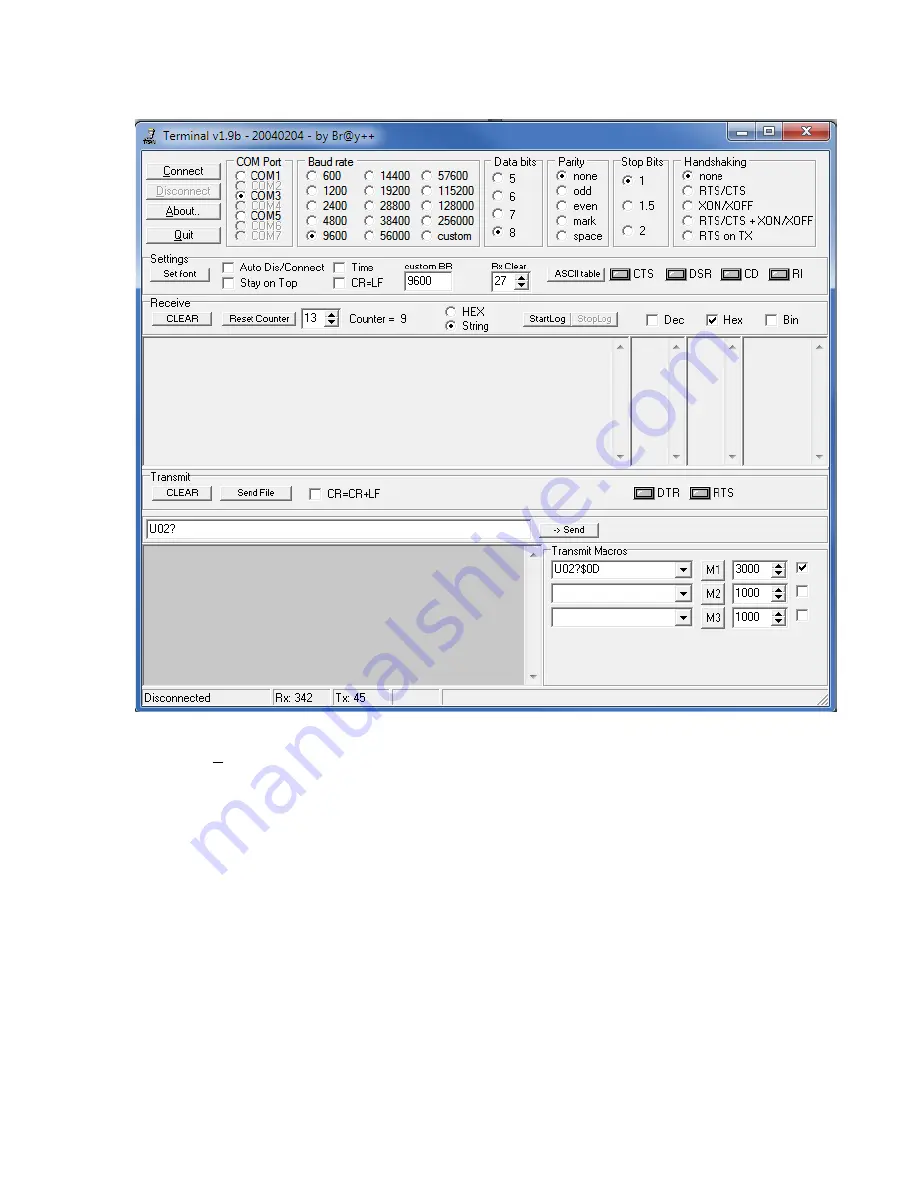

The Terminal application settings should be as below.

11.4.12

Click Connect.

11.4.13

Create a Transmit Macro that will send U02?$0D and check the checkbox to the right of

the macro definition. Note that the 02 in the macro represents the Poll Address of the

Model 706 device.

11.4.14

Verify that the Terminal application is receiving responses from the HMA and that there

are no communication errors being reported. The Receive buffer section should have the

same number of responses as the Transmit buffer section.

Summary of Contents for Jupiter JM4

Page 2: ......