Service Manual JET3

110

Rev. 1.0

3.

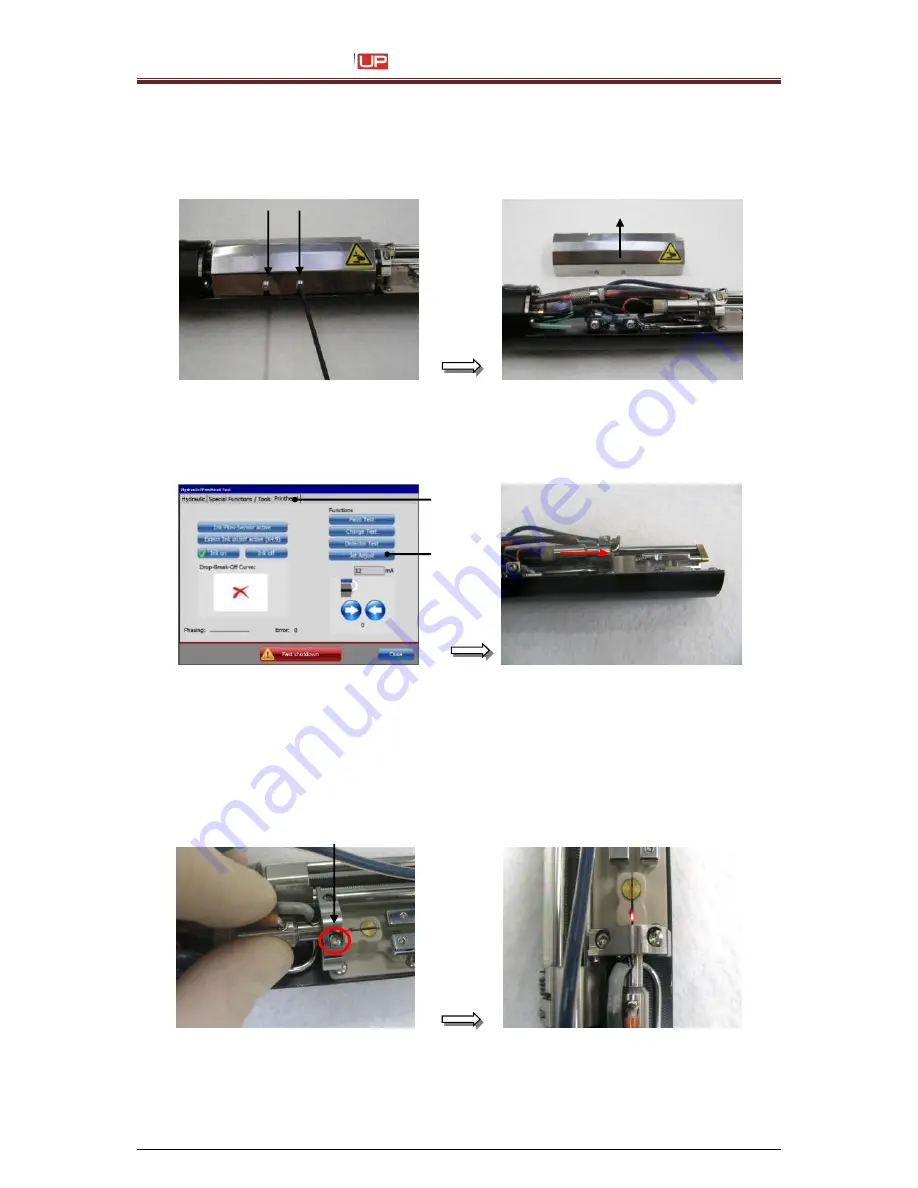

Remove the head cover and press the button

<Jet Adjust>

.

The nozzle seal opens automatically to the

<Jet adjust position>

(4200)

Unfix attachment screws around one rotation with hex key and take off the inside

cover.

4.

Switch to the tab

<Printhead>

(1) and press button

<Jet Adjust>

(2).

The nozzle seal opens automatically to the

<head adjustment position>

.

1

– Menu <Printhead>

2

–Button <Jet Adjust>

5.

Unfix the right attachment screw of the nozzle retainer just so far that you can adjust

the retainer manhandling. Maybe you need to unfix the second screw as well.

Caution

:

Use the right torx only!

Unfixing

right

attachment screw.

1

2

Summary of Contents for JET3 up

Page 1: ...SERVICE MANUAL ...

Page 12: ...Service Manual JET3 12 Rev 1 0 2 4 Safety sticker Figure 1 ...

Page 58: ...Service Manual JET3 58 Rev 1 0 7 2 Documentations for SK4 Torsional moments for SK4 ...

Page 99: ...Service Manual JET3 Rev 1 0 99 7 3 Documentations for SK6 Torsional moments for SK6 ...

Page 142: ...Service Manual JET3 142 Rev 1 0 ...

Page 144: ...Service Manual JET3 144 Rev 1 0 7 4 Hydraulic 1 Hydraulic scematic ...