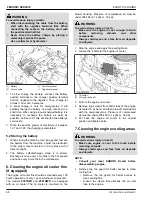

Lever position (high or low)

1. Remove the bolts and select the motion control

lever position, high or low.

2. Tighten the bolts.

(1) Bolt

(2) Flange nut

(3) Tab slot

(A) High position

Lever alignment (right and left)

1. Loosen the bolts.

2. Slide both levers forward or rearward to the desired

position within tab slots until the levers are aligned.

3. Tighten the bolts.

5. Adjusting the mower lift pedal

1. Stop the engine and apply the parking brake.

2. Loosen the nut and adjust the pedal position.

(1) Pedal

(2) Nut (M8)

(M) “MOVE”

3. Tighten the nuts.

MOWER DECK LEVEL

1. Anti-scalp rollers

WARNING

To avoid serious injury or death:

• Park the machine on a firm and level surface.

• Apply the parking brake.

• Stop the engine and remove the key.

• Wait for all moving parts to stop.

NOTE :

• The flattest cut can be achieved by having the

anti-scalp rollers adjusted off the ground.

Check the anti-scalp roller adjustments each

time the mower deck cutting height is changed.

It is recommended that all the anti-scalp rollers

be kept off the ground to minimize scuffing.

1. Check the machine tire pressure.

Inflate tires to the correct pressure.

(See TIRES AND WHEELS on page 50.)

2. Start the engine.

3. Raise up the mower deck to the top position.

4. Turn the cutting height control dial to adjust the

height.

5. Lower the mower deck.

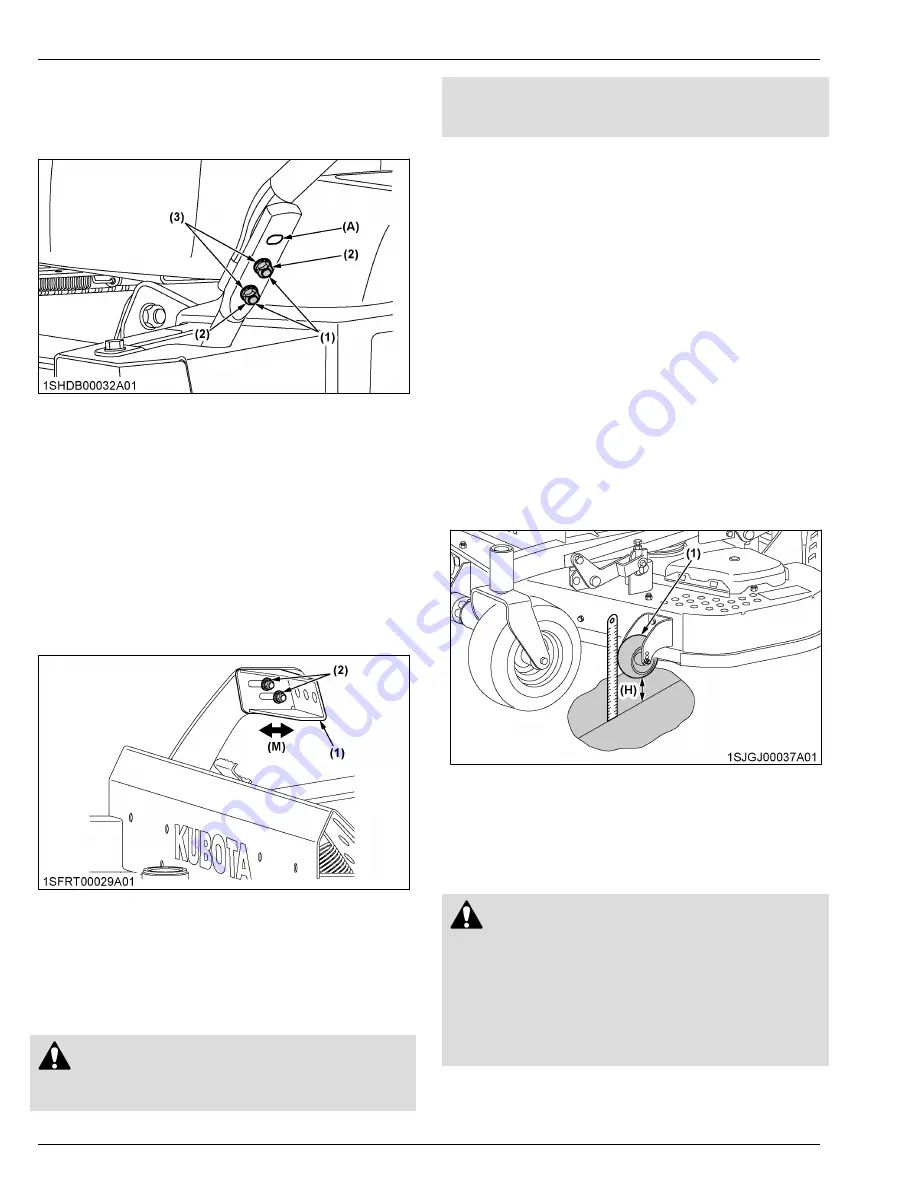

6. Adjust the height of the front side anti-scalp roller to

1 of the 3 positions, to approximately 19 mm

(0.75 in.) between the rollers and the ground.

Adjust the other 2 rollers to the same height.

(1) Front side anti-scalp roller

(H) 19 mm (0.75 in.)

7. Install the roller with the attaching hardware.

2. Leveling the mower deck (side-to-

side)

WARNING

To avoid serious injury or death:

• Park the machine on a firm and level surface.

• Apply the parking brake.

• Disengage the PTO (OFF).

• Stop the engine and remove the key while

checking or adjusting the level of the mower

deck.

IMPORTANT :

• Check the machine tire pressure.

ADJUSTMENT

MOTION CONTROL LEVER

82

Z751KWi,Z781KWi,Z781KWTi

Summary of Contents for Z751KWi

Page 3: ...OPERATOR S MANUAL 1SJGJ00001A01 READ AND SAVE THIS MANUAL MODELS Z751KWi Z781KWi Z781KWTi ...

Page 15: ...SAFETY LABELS SAFE OPERATION 10 Z751KWi Z781KWi Z781KWTi ...

Page 16: ...SAFE OPERATION Z751KWi Z781KWi Z781KWTi 11 ...

Page 17: ...SAFE OPERATION 12 Z751KWi Z781KWi Z781KWTi ...

Page 18: ...SAFE OPERATION Z751KWi Z781KWi Z781KWTi 13 ...

Page 19: ...SAFE OPERATION 14 Z751KWi Z781KWi Z781KWTi ...

Page 21: ...16 Z751KWi Z781KWi Z781KWTi ...