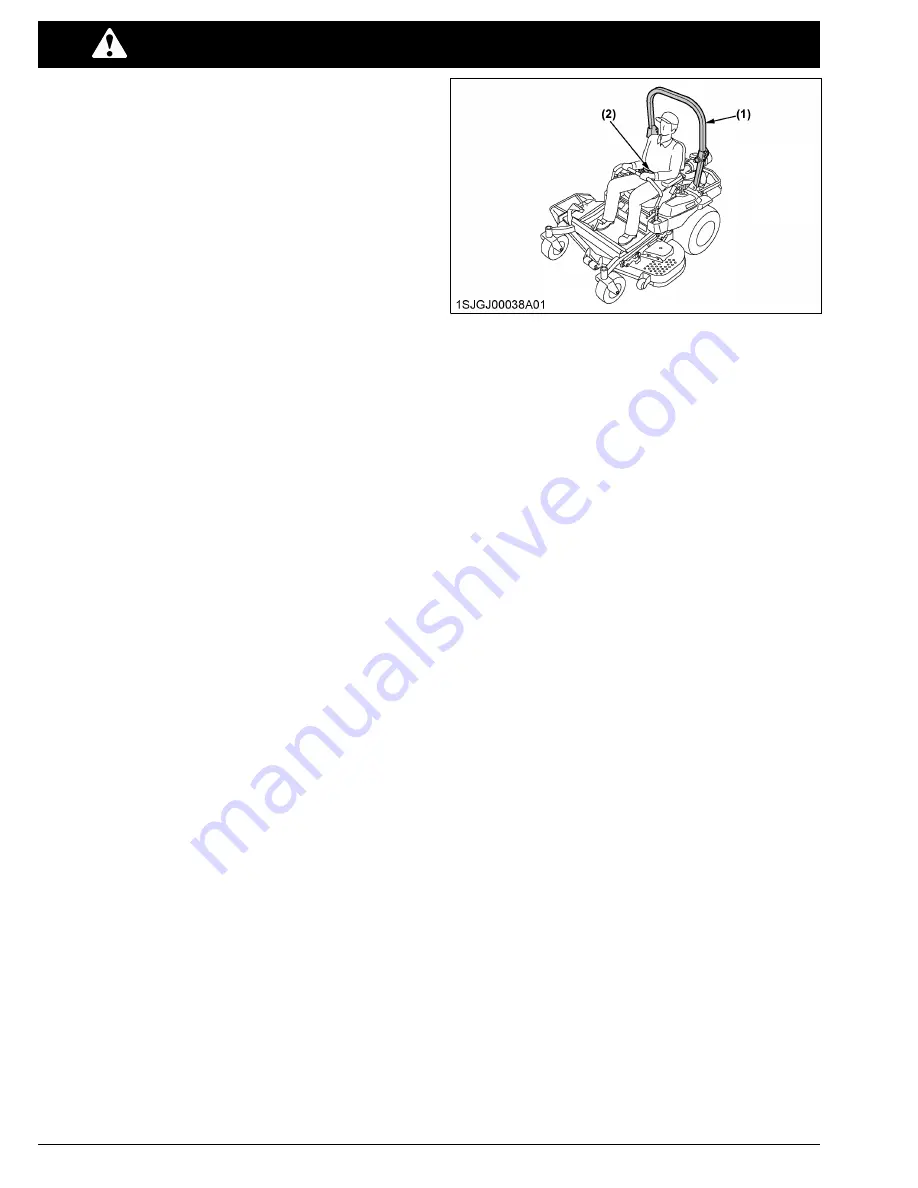

2. ROPS

• The ROPS is an integral and effective safety

device.

• KUBOTA recommends the use of a roll-over

protective structure (ROPS) and seat belt in almost

all applications. This combination will reduce the

risk of serious injury or death, should the machine

be upset.

• The machine is equipped with a foldable ROPS,

which may be temporarily folded down only when

absolutely necessary for areas with height

constraints.

There is no operator protection provided by the

ROPS in the folded position. For operator safety the

ROPS must be placed in the upright and locked

position and the seat belt fastened for all other

operations.

• Do not remove the ROPS.

• If the ROPS is loosened or removed for any reason,

make sure that all parts are reinstalled correctly

before operating the machine.

• Never modify or repair a ROPS because welding,

bending, drilling, grinding, or cutting may weaken

the structure.

• If any structural member of the ROPS is damaged,

replace the entire structure at your local KUBOTA

Dealer. Any alterations to a ROPS must be

approved by the manufacturer.

• Check the area to be mowed and never fold down a

foldable ROPS in areas where there are slopes,

drop-offs or water.

• Check carefully for overhead clearances (such as

branches, doorways and electrical wires) before

driving under any objects and do not contact them.

• Keep the ROPS in safe operating condition by

periodically and thoroughly inspecting for damage

and keeping all mounting fasteners tight.

• Always use the seat belt when the ROPS is upright.

Do not use the seat belt if the ROPS is down or if

there is no ROPS. Check the seat belt regularly and

replace if frayed or damaged. Be certain that the

seat belt can be released quickly in the event of an

emergency.

(1) ROPS

(2) Seat belt

OPERATING THE MACHINE

1. Starting to operate the machine

• Always sit in the operator's seat when starting the

engine or operating levers or controls.

• Before starting the engine make sure that the

motion control levers are in neutral lock, the parking

brake is applied, and the power take-off (PTO) is

disengaged (OFF).

• Do not start the engine by shorting across starter

terminals. The machine may start in gear and move

if the normal starting circuitry is bypassed.

• Do not operate or idle the engine in a non-

ventilated area. Carbon monoxide gas is colorless,

odorless, and deadly.

• Do not start the engine when the front or rear tires

are not on the ground.

• Check before each use that the operator presence

control (OPC) system is functioning correctly.

Test the safety systems.

(See Checking the engine start system on page

61 and Checking the OPC system on page 62.)

Do not operate unless they are functioning

correctly.

• Check all fluids before starting.

2. Working the machine

• Do not turn sharply when driving at high speed.

• To avoid tip-over accidents, slow down when

turning on uneven terrain or before stopping.

• Do not operate near ditches, holes, embankments,

or other terrain, which may collapse under the

machine's weight. The risk of machine tip-overs

increases when the ground is loose or wet.

• Park the machine on a firm and level surface.

Before you get off, apply the parking brake, place

the motion control levers in their neutral lock

positions,

disengage

the

PTO,

lower

all

attachments to the ground, turn off the engine, and

remove the key.

SAFE OPERATION

6

Z751KWi,Z781KWi,Z781KWTi

Summary of Contents for Z751KWi

Page 3: ...OPERATOR S MANUAL 1SJGJ00001A01 READ AND SAVE THIS MANUAL MODELS Z751KWi Z781KWi Z781KWTi ...

Page 15: ...SAFETY LABELS SAFE OPERATION 10 Z751KWi Z781KWi Z781KWTi ...

Page 16: ...SAFE OPERATION Z751KWi Z781KWi Z781KWTi 11 ...

Page 17: ...SAFE OPERATION 12 Z751KWi Z781KWi Z781KWTi ...

Page 18: ...SAFE OPERATION Z751KWi Z781KWi Z781KWTi 13 ...

Page 19: ...SAFE OPERATION 14 Z751KWi Z781KWi Z781KWTi ...

Page 21: ...16 Z751KWi Z781KWi Z781KWTi ...