The electric clutch serves 2 functions in the operation

of the mower:

• Starting and stopping the power flow to the cutter

blades.

• The clutch also acts as a brake to assist in stopping

blade rotation when the PTO is switched off or the

operator presence control is interrupted.

When the clutch is disengaged, the air gap between the

armature and rotor should be less than 2.5 mm

(0.100 in.) and more than 0.25 mm (0.010 in.). Perform

the following procedure to check the electric clutch

function.

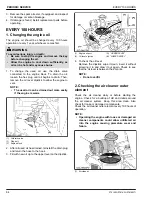

(1) Rotor

(2) Armature

(3) Shim

(4) Brake mounting bolt

(5) Aluminum spacers

(A) Air gap

1. Using a pneumatic line, blow out any debris from

under the brake pole and around the aluminum

spacers.

2. Check air gap between rotor and armature face on

both sides of the brake pole. If air gap is 2.5 mm

(0.100 in.) or greater, or if clutch is having trouble

engaging when hot, proceed to step 3. Otherwise,

skip to step 9.

3. Loosen both brake mounting bolts 1 full turn.

4. Use pliers or hand to remove the shim. Do not

discard shim until proper clutch function has been

confirmed.

5. Using a pneumatic line, blow out any debris from

under the brake pole and around the aluminum

spacers.

6. Tighten each brake mounting bolt. Torque to

13-14.2 N

⋅

m (9.5-10.5 lbf

⋅

ft).

7. Using a 0.25 mm (0.010 in.) thick feeler gage,

check that a gap is present between the rotor and

armature face on both sides of the brake pole.

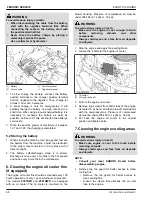

(P) Check gap on one side

(Q) Check gap on other side

8. If the gap is less than 0.25 mm (0.010 in.), reinstall

the shim and consult your local KUBOTA Dealer. If

gap is greater than 0.25 mm (0.010 in.), proceed to

next step.

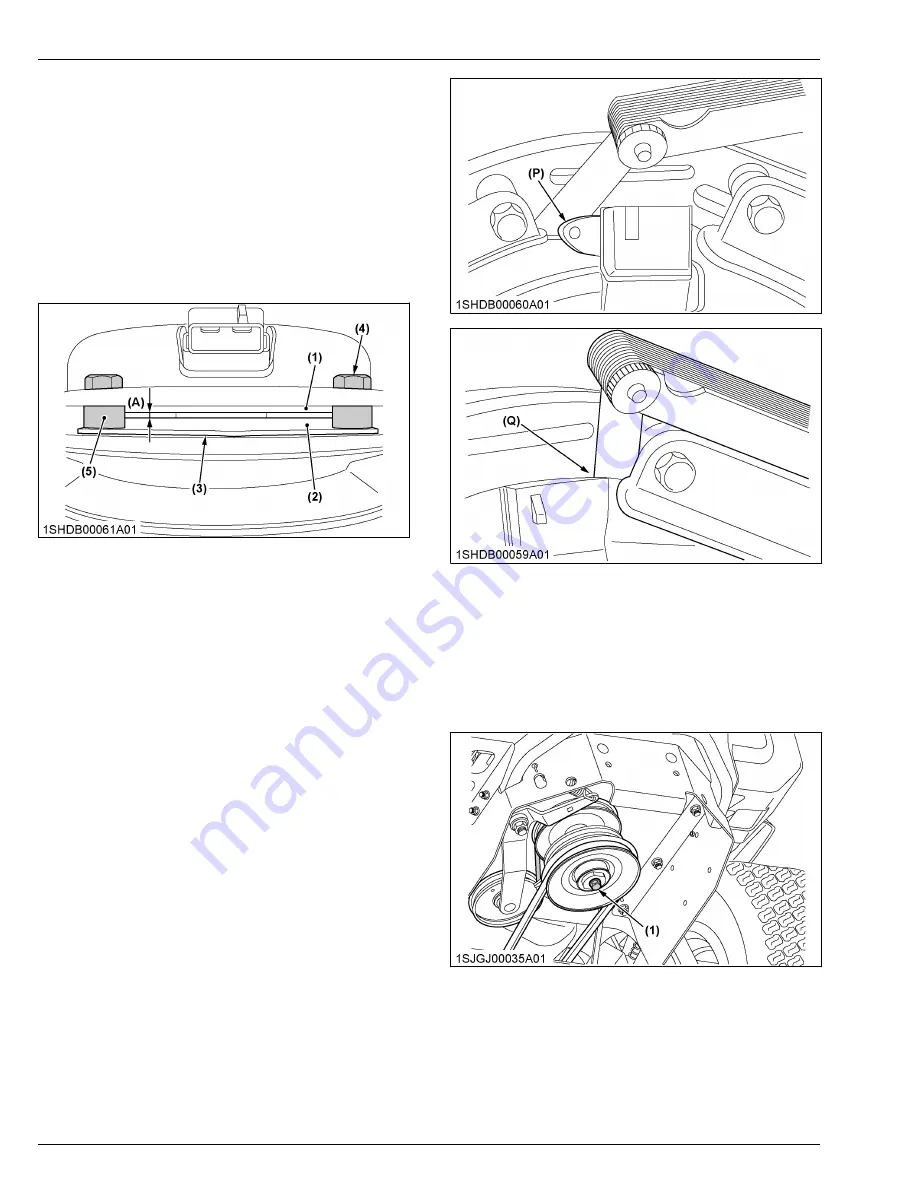

9. Check tightness of clutch mounting bolt. Torque to

67-75 N

⋅

m (50-55 lbf

⋅

ft).

(1) Clutch mounting bolt

10. With the engine running, check clutch function by

engaging and disengaging the clutch 10

consecutive times. If clutch does not engage,

consult your local KUBOTA Dealer.

This adjustment should be done every 500 hours of

operation or annually, whichever comes first. In case

PERIODIC SERVICE

EVERY 500 HOURS

74

Z751KWi,Z781KWi,Z781KWTi

Summary of Contents for Z751KWi

Page 3: ...OPERATOR S MANUAL 1SJGJ00001A01 READ AND SAVE THIS MANUAL MODELS Z751KWi Z781KWi Z781KWTi ...

Page 15: ...SAFETY LABELS SAFE OPERATION 10 Z751KWi Z781KWi Z781KWTi ...

Page 16: ...SAFE OPERATION Z751KWi Z781KWi Z781KWTi 11 ...

Page 17: ...SAFE OPERATION 12 Z751KWi Z781KWi Z781KWTi ...

Page 18: ...SAFE OPERATION Z751KWi Z781KWi Z781KWTi 13 ...

Page 19: ...SAFE OPERATION 14 Z751KWi Z781KWi Z781KWTi ...

Page 21: ...16 Z751KWi Z781KWi Z781KWTi ...