3. If the rotation strength is too high, clean the dial

cam area and apply grease under the dial cam

between the dial cam and the frame.

(1) Dial cam

(2) Frame surface

(R) “ROTATE”

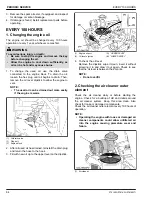

7. Cleaning area around safety

switches

Since debris decreases the performance of safety

switches, it is necessary to keep the area around the

safety switches.

1. Clean the area around the safety switches.

(1) Parking brake pedal switch

(2) Motion control lever switch

(3) PTO switch

(4) Seat switch

8. Checking movable parts

If any of the movable parts, such as levers and pedals,

cannot be smoothly moved because of rust or anything

sticky, do not attempt to force it into motion.

In this case, remove the rust or the sticky object, and

apply oil or grease on the relevant spot. Otherwise, the

machine may get damaged.

EVERY 50 HOURS

1. Checking the engine start system

The engine start system in your machine is designed to

protect you while operating. Check the engine start

system periodically (daily is best) to test the function of

the engine start system before operation.

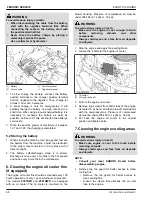

WARNING

To avoid serious injury or death:

• Do not allow anyone near the machine while

testing.

• If the machine does not pass one of the

following tests, do not operate the machine.

Consult your local KUBOTA Dealer.

• Sit on the operator's seat for all tests except for

test 1.

IMPORTANT :

• Test the following before operating the

machine:

(1) Parking brake pedal

(2) Motion control lever

(3) Key switch

(4) PTO switch

(5) Seat switch

Test 1 (operator not on the seat)

1. Sit in seat and securely set the parking brake.

2. Set the PTO switch to the

“DISENGAGE”

(OFF)

position.

3. Set the motion control levers to the

“NEUTRAL

LOCK”

position.

4. Stand up. Do not get off the machine.

5. Turn the key switch to the

“START”

position.

6. The engine must not crank.

Test 2 (operator on the seat)

1. Do not set the parking brake (release it from test 1).

2. Set the PTO switch to the

“DISENGAGE”

(OFF)

position.

3. Set the motion control levers to the

“NEUTRAL

LOCK”

position.

4. Turn the key switch to the

“START”

position.

DAILY CHECK

PERIODIC SERVICE

Z751KWi,Z781KWi,Z781KWTi

61

Summary of Contents for Z751KWi

Page 3: ...OPERATOR S MANUAL 1SJGJ00001A01 READ AND SAVE THIS MANUAL MODELS Z751KWi Z781KWi Z781KWTi ...

Page 15: ...SAFETY LABELS SAFE OPERATION 10 Z751KWi Z781KWi Z781KWTi ...

Page 16: ...SAFE OPERATION Z751KWi Z781KWi Z781KWTi 11 ...

Page 17: ...SAFE OPERATION 12 Z751KWi Z781KWi Z781KWTi ...

Page 18: ...SAFE OPERATION Z751KWi Z781KWi Z781KWTi 13 ...

Page 19: ...SAFE OPERATION 14 Z751KWi Z781KWi Z781KWTi ...

Page 21: ...16 Z751KWi Z781KWi Z781KWTi ...