PRINT PROCESS DESCRIPTION

H325 IAE

Rev.: 004

kortho

QiC i-series

3-3

3.4.1 Menu structure

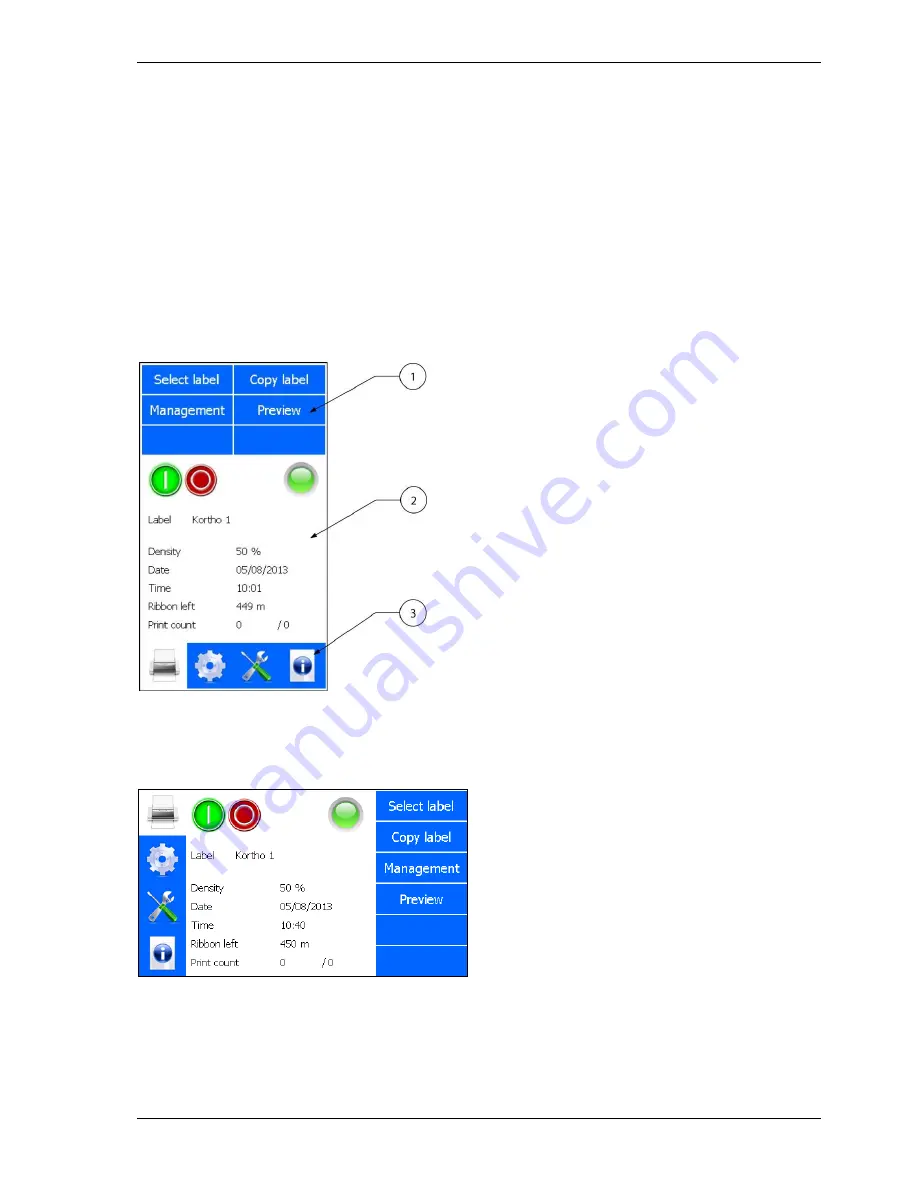

The screen is divided in three parts, see Fig. 3.1. Section 1 shows the submenus available when the printer

icon is selected. When the other icons in section 3 are selected, different submenus will be shown. Section 2 is

showing the status of the printer and the Start (I) \ Pause (0) button. Depending on the button selected in

section 1 and 3 the content of this section will change.

The content can be settings, status information or general information. Section 3 is showing the 4 main menu

options:

1.

Label selection/Label management.

2.

Printer settings.

3.

Diagnostics.

4.

Information.

Fig. 3.1

Screen layout, main menu portrait

The standard factory setting for the menu is portrait mode. Alternatively the screen can be displayed in

landscape mode. The screen can be rotated by steps of 90 degrees, see section 8.6.1.

Fig. 3.2

Screen layout, main menu landscape

1.

Section 1, sub menu items

2.

Section 2, status, options and

preview area

3.

Section 3, main menu items

Summary of Contents for qic i series

Page 1: ...MANUAL QiC i series Thermal Transfer Printer Edition H325 IAE Rev 004 English kortho...

Page 14: ...INTRODUCTION kortho QiC i series H325 IAE Rev 004 1 6...

Page 30: ...PRINT PROCESS DESCRIPTION kortho QiC i series H325 IAE Rev 004 3 10...

Page 38: ......

Page 42: ...TRANSPORT STORAGE kortho QiC i series H325 IAE Rev 004 5 4...

Page 110: ...MAINTENANCE kortho QiC i series H325 IAE Rev 004 10 6...

Page 120: ...APPENDIX A SPECIFICATIONS kortho QiC i series H325 IAE Rev 004 A 4...

Page 133: ...APPENDIX C PART LISTS ILLUSTRATIONS H325 IAE Rev 004 kortho QiC i series C 7 Magazine QiC 30i...

Page 159: ...APPENDIX C PART LISTS ILLUSTRATIONS H325 IAE Rev 004 kortho QiC i series C 33...

Page 160: ...APPENDIX C PART LISTS ILLUSTRATIONS kortho QiC i series H325 IAE Rev 004 C 34...

Page 163: ...APPENDIX D CONNECTIONS H325 IAE Rev 004 kortho QiC i series D 3 X3 Schematic diagram input...

Page 164: ...APPENDIX D CONNECTIONS kortho QiC i series H325 IAE Rev 004 D 4 X3 Schematic diagram output...

Page 165: ...APPENDIX D CONNECTIONS H325 IAE Rev 004 kortho QiC i series D 5 X3 Circuit diagram input...

Page 166: ...APPENDIX D CONNECTIONS kortho QiC i series H325 IAE Rev 004 D 6 X3 Circuit diagram output...

Page 181: ...H325 IAE Rev 004 kortho QiC i series F 1 Appendix F Quick reference...

Page 182: ...APPENDIX F QUICK REFERENCE Kortho QiC i series H325 IAE Rev 004 F 2...

Page 186: ...bv korthofah P O box 3040 2220 CA Katwijk The Netherlands...