Check and maintenance

items

Content of check, maintenance

Guideline for maintenance interval

Refrigerant (gas)

Charge amount

Twice a year (spring, autumn)

Air conditioner condens-

er

Clogged fins

Every 500 hours

“METHOD FOR CHECKING AND CLEAN-

ING RADIATOR FINS, OIL COOLER FINS,

FUEL COOLER FINS, AND AIR CONDI-

TIONER CONDENSER FINS”

Air conditioner compres-

sor

Operating condition

Every 4000 hours

V-belt

Damage, tension

Every 250 hours

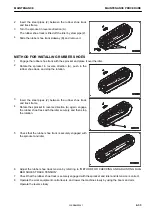

“METHOD FOR CHECKING AND ADJUST-

ING AIR CONDITIONER COMPRESSOR

BELT TENSION”

Blower motor, fan

Operating condition (Check for un-

usual noise)

When required

Control mechanism

Operating condition (Check that

function is normal)

When required

Piping mounts

Mounting condition, looseness at

tightening or connecting portions,

leakage of gas, damage

When required

Even during the off-season, operate the air conditioner for 3 to 5 minutes once a month to maintain the oil film at

all parts of the air conditioner compressor.

TEST THE LEVEL OF REFRIGERANT FOR AIR CONDITIONER (GAS)

k

k

WARNING

• Never touch the refrigerant.

Do not loosen any part of the refrigerant circuit.

If the refrigerant used in the air conditioner gets into your eyes or is splashed on your hands, it may

cause loss of sight or frostbite.

• Do not bring any open flame close to any point where the refrigerant (gas) is leaking.

If the level of the refrigerant (gas) is low, the cooling effect will be reduced. Perform the check while running the

engine at high idle and operating the air conditioner at high speed.

Check the condition of the refrigerant gas (Hydrofluorocarbons HFC-134a) that circulates the refrigerant circuit,

through the sight glass (1) (inspection window) of the receiver.

(A) Proper

No bubbles in refrigerant flow

(B) Insufficient

Some bubbles in refrigerant flow (bubbles pass continuously)

(C) None

Transparent with no color

REMARK

When there are bubbles, the refrigerant (gas) level is low, so ask your Komatsu distributor to add refrigerant. If

the air conditioner continues to run with low refrigerant (gas) level, it will cause damage to the compressor.

RKA68830

MAINTENANCE PROCEDURE

MAINTENANCE

4-38

WENAM00241

Summary of Contents for PC80MR-5E0

Page 2: ......

Page 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Page 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Page 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Page 343: ...SPECIFICATIONS 5 1 WENAM00241...

Page 394: ...WENAM00241...

Page 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Page 411: ......

Page 412: ......