2.

Set the lock lever to FREE position (F).

3.

Place the machine on a firm, level ground.

4.

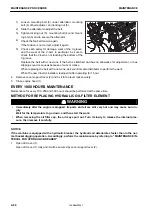

Set the work equipment to the posture shown in the figure

according to the following procedure.

1) Operate the work equipment control levers, and re-

tract arm cylinder and bucket cylinder to their stroke

end (maximum reach posture of arm and bucket).

2) Operate the boom swing control pedal to swing the

boom to the center position.

3) Operate the work equipment control lever, and raise

the work equipment to height (a) of 1.5 m and hold

there.

5.

Set the lock lever to LOCK position (L).

6.

Check nitrogen gas charge pressure in accumulator within 15 seconds according to the following proce-

dure.

When the engine is stopped, the pressure in the accumulator gradually goes down, so this inspection can

be performed only immediately after the engine is stopped.

1) Turn the starting switch to OFF position (A) to stop the

engine.

Hold the work equipment in the maximum reach pos-

ture (arm fully out, bucket fully dumped).

RKA63210

MAINTENANCE PROCEDURE

MAINTENANCE

4-70

WENAM00241

Summary of Contents for PC80MR-5E0

Page 2: ......

Page 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Page 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Page 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Page 343: ...SPECIFICATIONS 5 1 WENAM00241...

Page 394: ...WENAM00241...

Page 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Page 411: ......

Page 412: ......