1.

Set the working mode to P mode on the machine monitor

(1).

It quickens the warm-up of the hydraulic component.

For the working mode setting, see “WORKING MODE SE-

LECTION”.

2.

Move the lock lever (2) slowly and securely to FREE posi-

tion (F).

Operate the R.H. and L.H. work equipment control levers

(3) and (4) slowly to raise the bucket from the ground.

3.

Turn the fuel control dial (5) to the point (c) of 2/3 between

Low idle (MIN) position (a) and High idle (MAX) position

(b).

4.

Operate the R.H. and L.H. work equipment control levers

(3) and (4) to warm up the hydraulic components.

Repeat the operation of the R.H. and L.H. work equipment

control levers (3) and (4) for 5 minutes.

NOTICE

When the work equipment is operated, take care that it

does not interfere with the machine or ground.

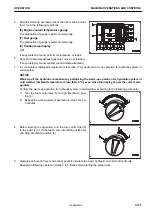

1) Operate the R.H. work equipment control lever (4)

slowly to set it to bucket CURL position (m).

Keep the lever at bucket CURL position (m) for 30

seconds.

2) Operate the R.H. work equipment control lever (4) slowly to set it to the bucket DUMP position (k).

Keep the lever at the bucket DUMP position (k) for 30 seconds.

3) Operate the L.H. work equipment control lever (3) slowly to set it to the arm IN position (f).

Keep the lever at the arm IN position (f) for 30 seconds.

4) Operate the L.H. work equipment control lever (3) slowly to set it to the arm OUT position (g).

Keep the lever at the arm OUT position (g) for 30 seconds.

RKA63210

RKA63962

MACHINE OPERATIONS AND CONTROLS

OPERATION

3-126

WENAM00241

Summary of Contents for PC80MR-5E0

Page 2: ......

Page 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Page 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Page 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Page 343: ...SPECIFICATIONS 5 1 WENAM00241...

Page 394: ...WENAM00241...

Page 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Page 411: ......

Page 412: ......