1.

Pump in grease through grease fitting (4) by using a

grease pump.

If the tension is still low after the grease is pumped in, ask

your Komatsu distributor to replace the rubber shoe or seal

in the cylinder.

2.

To check if the tension is correct, run the engine at low

idle, and move the machine slowly forward by an amount

equal to the length of track on ground.

3.

Check the rubber shoe track tension again. If it is not cor-

rect, adjust it again.

METHOD FOR DECREASING RUBBER SHOES TRACK TENSION

k

k

WARNING

• Grease is pumped into the track tension adjustment

system under high pressure.

If the adjustment is performed with the procedure oth-

er than following, grease drain plug (5) may fly out and

cause serious injury or death.

• Do not loosen grease drain plug (5) more than 1 turn.

• Do not loosen any part other than grease drain plug

(5).

• Do not put your face, hands, feet, or any other part of

your body close to grease drain plug (5).

1.

Loosen grease drain plug (5) gradually to release the grease.

If the grease does not come out smoothly, move the machine forward and backward a short distance.

2.

Tighten grease drain plug (5).

3.

To check if the tension is correct, run the engine at low idle, and move the machine slowly forward by an

amount equal to the length of track on ground.

4.

Check the track tension again, and if the tension is not correct, adjust it again.

If the track tension cannot be decreased by the above procedure, ask your Komatsu distributor for repair.

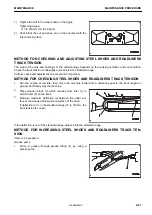

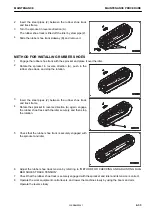

METHOD FOR REPLACING RUBBER SHOES

k

k

WARNING

• Perform the operation with 2 workers. The operator must operate the machine according to the

signs of the worker.

• The machine must be raised to replace the rubber shoes. If the machine falls by accident at this

time, it is very dangerous.

Never move any part other than the rubber shoes to be replaced during the replacement work.

Also, never put your body under the rubber shoes or track frame during the replacement work.

NOTICE

The idler cushion must be removed and adjusted when the rubber shoes are replaced with the steel

shoes or road liner. Accordingly, be sure to ask your Komatsu distributor to perform the work.

Items to be prepared

• Grease pump

• Steel pipe

Set the machine to the following conditions before replacing the rubber shoes.

MAINTENANCE

MAINTENANCE PROCEDURE

4-31

WENAM00241

Summary of Contents for PC80MR-5E0

Page 2: ......

Page 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Page 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Page 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Page 343: ...SPECIFICATIONS 5 1 WENAM00241...

Page 394: ...WENAM00241...

Page 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Page 411: ......

Page 412: ......