5 Diagrams

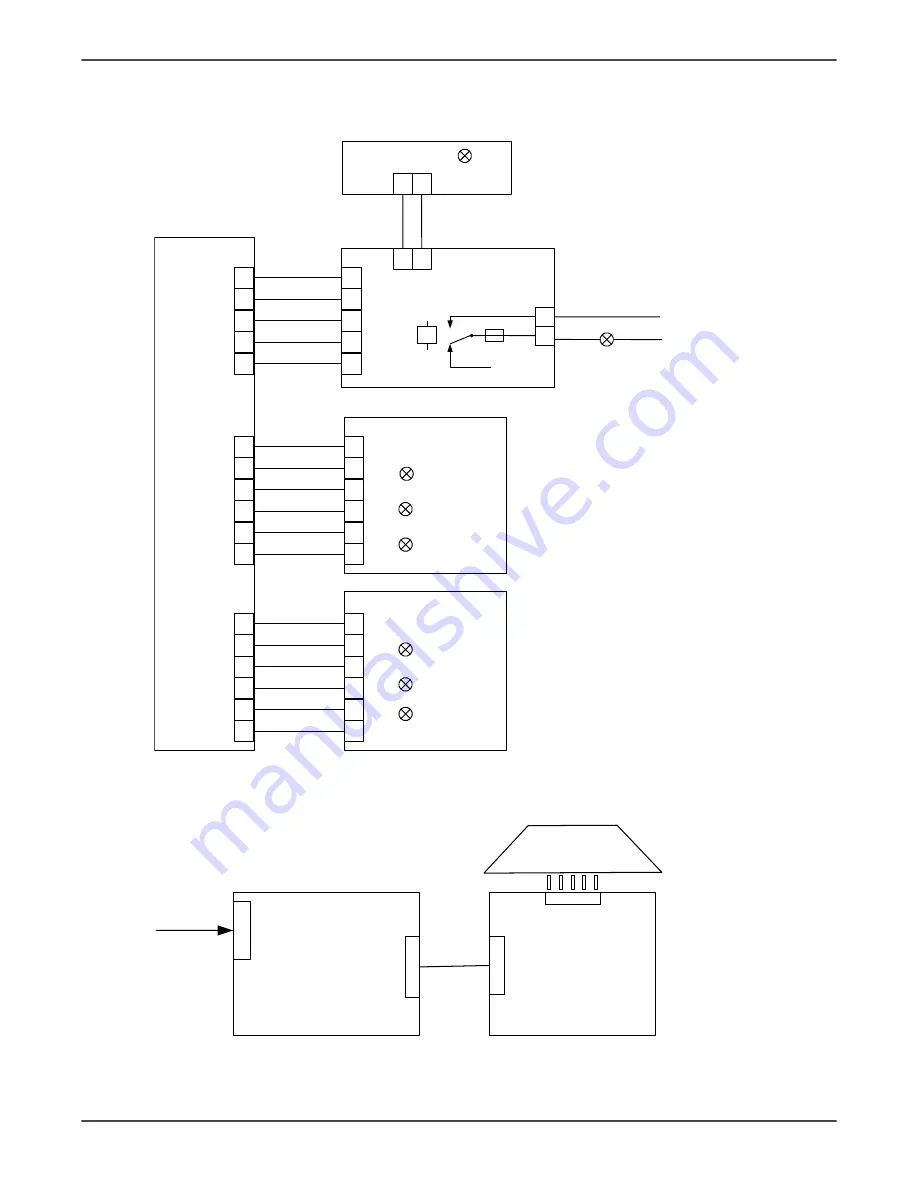

5.18 Exposure warning light

3

5 6

5 6

Remote controller

Exposure

warning

J4104/

J4102

1

J4105

External

warning

lamp

i4100

i4000

J4101

J4013

J4007

J6001

i6000

Exposure

warning

Error

Ready

J8000

i8000

Exposure

warning

Error

Ready

J4022

7

8

12

13

3

7

8

12

13

1

2

8

9

6

10

1

2

8

9

6

10

1

2

3

4

5

6

1

2

3

4

5

6

2

F3

5.19 Device control panel

i6000

J6001

i4000

J4007

J4009

CAN

BUS

FROM

i3000

Positioning

panel

54

ORTHOPANTOMOGRAPH

™

OP 3D