Making operational:

1. Reconnect the negative battery terminal.

2. Close the door.

Dispose of old parts and contaminated materials according to environmental regulations.

Starting the machine and performing a test run:

1. Switch the machine on and run it in IDLE mode for approx. 5 minutes.

2. Shut down the machine.

3. Wait until the machine has automatically vented.

Pressure gauge reads 0 bar.

4. Open the outlet valves.

5. Open the right-hand access door.

6. Visually inspect for leaks.

7. Shut down the machine.

8. Close the door.

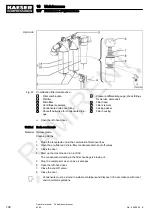

10.4.6 Changing the Oil Separator Cartridge

The oil separator element cannot be cleaned.

The life of the oil separator cartridge is influenced by:

■ contamination in the air drawn into the compressor,

■ and adherence to the changing intervals for:

─ Cooling oil

─ Oil filter

─ Air filters

Material Spares

Cleaning cloth

Wrench

Precondition The machine is shut down.

The machine is fully vented, the pressure gauge reads 0 bar.

Machine is cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

The negative cable to the battery is disconnected.

➤ Open the right-hand access door.

10 Maintenance

10.4 Compressor Maintenance

No.: 9_5898 26 E

Operator manual Portable compressor

M 64

129

RAMIRENT