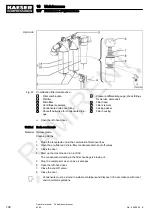

Fig. 71 Maintain the engine air shut-off valve

1

Engine air intake

2

Engine air filter

3

Air inlet hose (engine side)

4

Air inlet hose (air filter side)

5

Engine air shut-off valve

6

Hose clamp

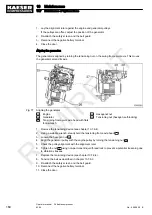

➤ Open both doors.

Clean the engine air shut-off valve:

1.

NOTICE!

The engine air intake shut-off valve does not close fully.

The machine does not shut down? Destruction of the engine and explosion and/or fire are

possible.

➤ Do not grease the valve, as this may cause a build up of dust and valve sticking.

2. Loosen the hose clamp on the filter side of the valve and turn the air intake hose to one side.

3. Check if the interior of the shut-off valve is clean.

Engine shut-off valve is clogged: Blow out with compressed air.

If necessary, clean the valve with cleaning fluid or spirit and allow to dry.

If dirt cannot be removed: Contact specialist workshop or KAESER SERVICE.

Checking the engine air intake shut-off valve for correct function and movement:

1. Check the valve for signs of excessive wear.

2. Check that the valve plate closes fully and easily.

Result When severe wear or function problems are apparent: Have the engine air intake valve replaced.

1. Reposition the air intake hose and tighten the clamp.

2. Close the doors.

3. Start the machine and switch to LOAD operation.

The engine stops in LOAD operation: Have the engine air intake valve checked by a specialist

workshop or KAESER SERVICE.

10 Maintenance

10.7 Maintenance of Optional Items

No.: 9_5898 26 E

Operator manual Portable compressor

M 64

153

RAMIRENT