Triton Go Product Manual |

Wiring and Connections

INGENIA | 05/29/2017

77

Refer to

Feedback wiring recommendations

for more information about connections and wires.

7.4.7 Analog input feedback

Triton Go Servo Drive can also use analog feedback systems connected through the I/O connector. From the

voltage level of one analog input, the position or velocity of the rotor can be calculated. The Triton Go have 2

analog inputs that can be used for feedback input, each one with a different input range. The input used as

feedback can be selected by software. Further specifications about the analog inputs input can be found in

Refer to

Feedback wiring recommendations

for more information about connections and wires.

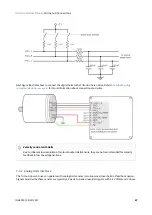

Potentiometer

Typically, a potentiometer is used as a postition feedback, providing a a voltage proportional to the rotor

position.

The following picture shows how to connect a potentiometer as a position sensor using analog input 1:

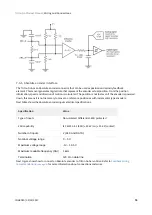

Recommended potentiometer resistance

Potentiometers with high values of resistance (> 10 k

Ω

) can result in non linear behavior due to its the

drive parallel input resistors. High resistance values also reduce the signal to noise ratio, making it

easier to have disturbances and reducing the quality of the measure.

However, a very small value of resistance may also consume too much power and cause self heating

(which causes additional variations on resistance). Therefore,

use the smallest value of resistance

that:

•

Does not exceed 1/2 of the potentiometer power rating (safety margin to prevent self heating).

•

Does not exceed the +5V_OUT current capacity.

Typically 1 k

Ω

to 10 k

Ω

will be preferred.