Triton Go Product Manual |

Wiring and Connections

INGENIA | 05/29/2017

83

Input current

0.17 mA @ 5 V; 0.5 mA @ 15 V

High level input voltage

( - HS_GPI-) > 150 mV

Low level input voltage

( - HS_GPI-) < -600 mV

Maximum working input voltage

±24 V

Maximum recommended frequency

10 MHz

Sampling rate

20 Msps

Total rising delay

65 ns

Total falling delay

55 ns

Maximum common mode voltage (V

CM

)

-7 V ≤ V

CM

≤ 12 V

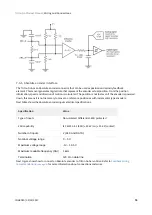

Next figure shows the circuit model for high-speed digital input. Input is composed of a 3-resistor differential

divider, with 10 k

Ω

resistors, resulting in a total input impedance of 30 k

Ω

. This

bias resistors allow both

single ended and differential input operation

. Noise immunity can be improved by reducing input impedance

with a termination resistor between and HS_GPI-.

High-speed digital inputs electrical equivalent circuit is the following: