SECTION 1 INTRODUCTION

LifeCare PCA

1 - 2

Technical Service Manual

❏

Section 7 Replaceable Parts and Repairs

❏

❏

❏

If a problem in device operation cannot be resolved using the information in this manual,

.

Specific instructions for operating the device are contained in its respective

System

Operating Manual

.

The terms “infusion system”, “infuser”, and “device” are used interchangeably throughout

the manual.

Figures are rendered as graphic representations to approximate actual product.

Therefore, figures may not exactly reflect the product. Screen representations

are examples only, and do not necessarily reflect the most current configuration.

1.3

CONVENTIONS

The conventions listed in

are used throughout this manual.

Throughout this manual, warnings, cautions, and notes are used to emphasize important

information, as follows:

Note:

A note highlights information that helps explain a concept or procedure.

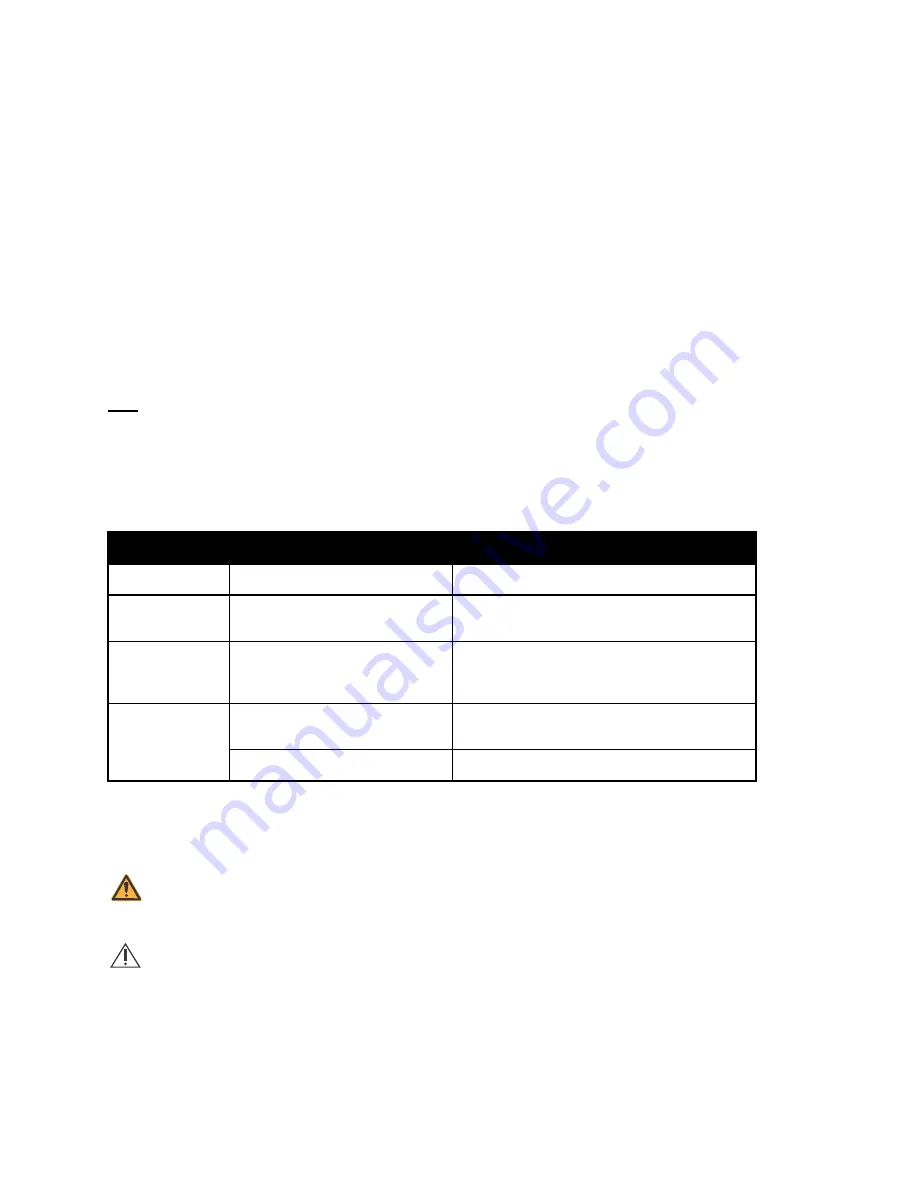

Table 1-1. Conventions

Convention

Application

Example

Italic

Reference to a section, figure,

table, website, or publication

(see Section 6.1)

[ALL CAPS]

ALL CAPS

In-text references to keys,

touchswitches, and display

messages

[START]

LOW BATTERY

Bold

Emphasis

CAUTION: Use proper ESD grounding

techniques when handling components.

Screen displays

Select

Set Time and Date

.

WARNING: A WARNING CONTAINS SPECIAL SAFETY EMPHASIS AND MUST

BE OBSERVED AT ALL TIMES. FAILURE TO OBSERVE A WARNING MAY RESULT

IN PATIENT INJURY AND BE LIFE-THREATENING.

CAUTION:

A CAUTION usually appears in front of a procedure or statement.

It contains information that could prevent hardware failure, irreversible

damage to equipment, or loss of data.