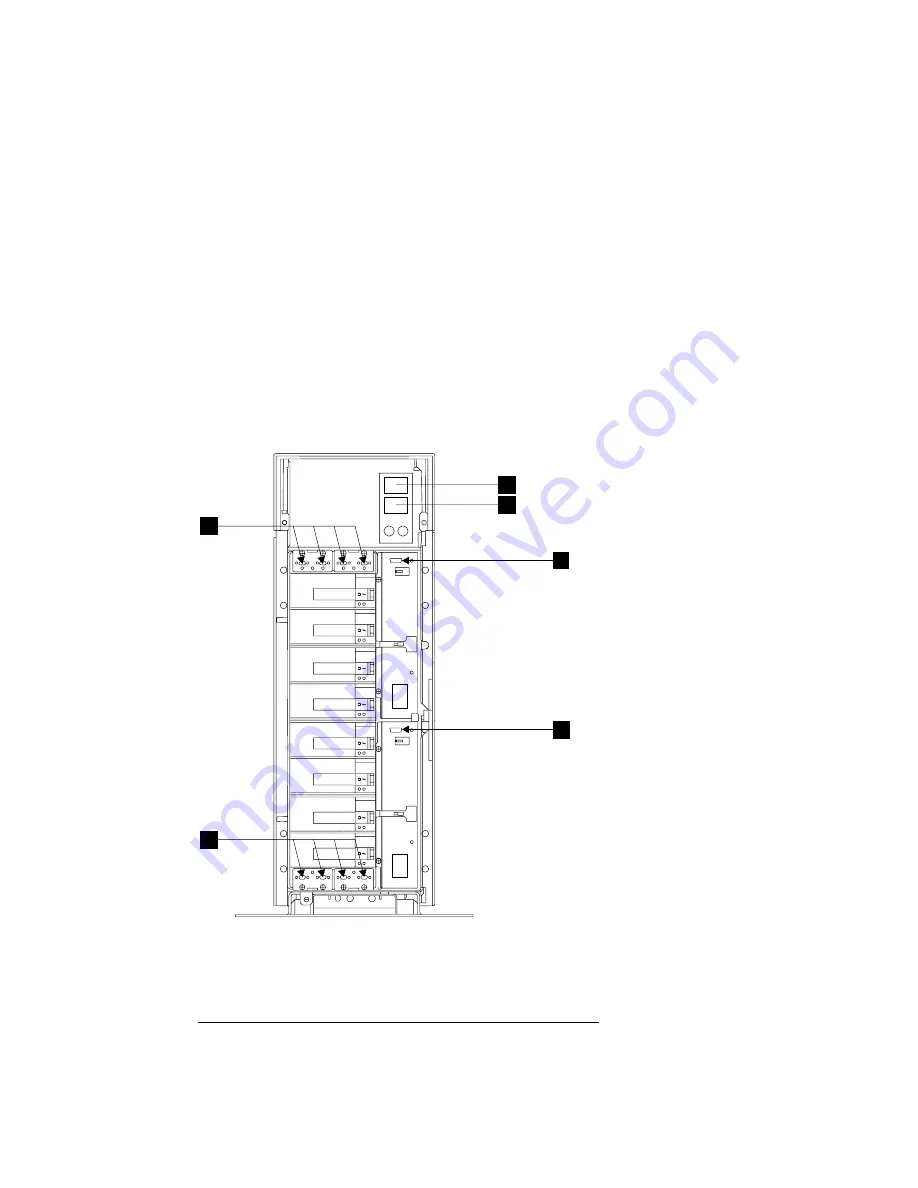

Back Connectors (Model T40)

1

Mainline power connectors

2

Reserved

3

Power control connector

4

SSA connectors

Table 4. Relationship between Strings and Connectors of Model

T40

Connectors

Disk Drive Modules

1 and 4

Front disk drive modules 1 through 4

5 and 8

Front disk drive modules 5 through 8

9 and 12

Back disk drive modules 9 through 12

13 and 16

Back disk drive modules 13 through 16

3

2

1

1

4

4

Figure 13. Back Connectors of Model T40

Chapter 1. Reference Information

29

Summary of Contents for 7133 D40

Page 1: ...7133 Models D40 and T40 Serial Disk Systems Service Guide GY33 0192 07 ...

Page 2: ......

Page 3: ...7133 Models D40 and T40 Serial Disk Systems Service Guide GY33 0192 07 ...

Page 10: ...viii 7133 Models D40 and T40 Service Guide ...

Page 14: ...xii 7133 Models D40 and T40 Service Guide ...

Page 90: ...72 7133 Models D40 and T40 Service Guide ...

Page 260: ...Assembly 1 7133 Model D40 242 7133 Models D40 and T40 Service Guide ...

Page 262: ...Assembly 1 continued 244 7133 Models D40 and T40 Service Guide ...

Page 264: ...Assembly 1 continued 246 7133 Models D40 and T40 Service Guide ...

Page 292: ...274 7133 Models D40 and T40 Service Guide ...

Page 305: ......

Page 306: ...Part Number 18P6104 Printed in the U S A GY33 0192 07 1P P N 18P6104 ...