Chapter 4 Electrical Installation

Shenzhen Hpmont Technology Co., Ltd.

- 32 -

HD3N Series User Manual V1.1

4.5

Meet EMC Requirement of Installation

4.5.1

Correct EMC Installation

According to national standards GB/T12668.3, the controller should meet the two requirements of

electromagnetic interference (EMI) and anti-electromagnetic interference. The international standards

IEC/61800-3 (VVVF drive system part 3: EMC specifications and test methods) are identical to the

national standards GB/T12668.3.

HD3N are designed and produced according to the requirements of IEC/61800-3. Please install the

controller as per the description below so as to achieve good electromagnetic compatibility (EMC).

•

In a drive system, the controller, control equipment and sensors are installed in the same cabinet;

the electromagnetic noise should be suppressed at the main connecting points, and the EMI filter

and AC reactor installed in cabinet to satisfy the EMC requirements.

•

The most effective but expensive measure to reduce the interference is to isolate the noise source

and the noise receiver, which should be considered in mechanical system design phase. In driving

system, the noise source can be controller, braking unit and contactor. Noise receiver can be

automation equipment, encoder and sensor etc.

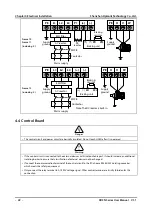

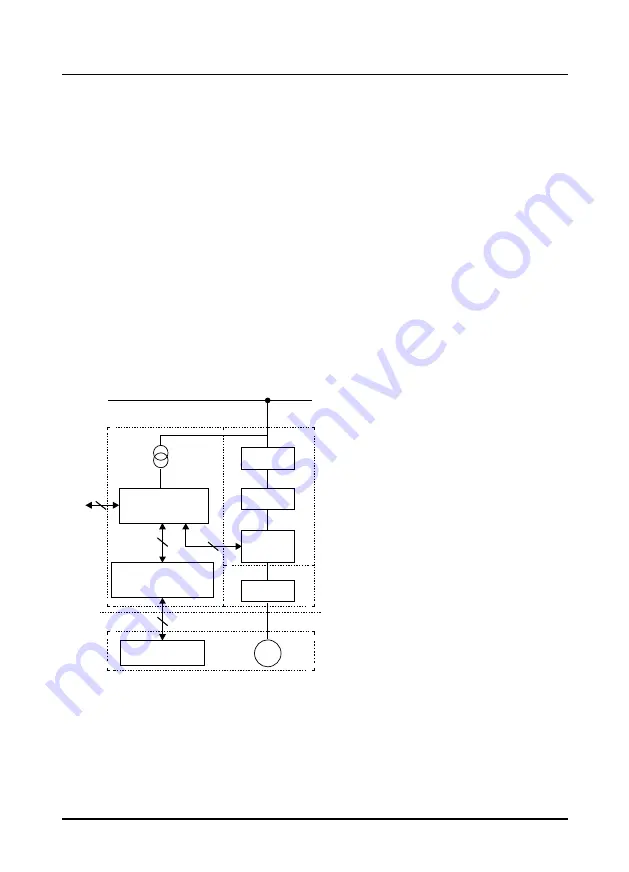

The mechanical/system is divided into different EMC areas according to electrical characteristics. The

recommended installation positions are shown in Figure 4-15.

Figure 4-15 System wiring

Explanation:

•

All areas should be isolated in space to achieve electromagnetic decoupling effect.

•

The min. distance between areas should be 20cm, and use grounding bars for decoupling among

areas, the cables from different area should be placed in different tubes.

•

EMI filters should be installed at the interfaces between different areas if necessary.

•

All of the communication cables from and signal cable from panel must be shielded.

Mains power supply

Inverter

Sensor (temperature,

liquid level sensor) etc.

Control device (the

host PC, PLC etc.)

EMI filter

Mechanical system

Motor

EMI filter

AC reactor

Manufacture machines

Earth isolated board

Power supply control cabinet

Area F

Area A

Area B

Area C

Area D

Area E

Area A

: transformers of control power

supply, control devices and sensor etc.

Area B

: interfaces of signal and control

cables, correct immunity is required.

Area C

: noise sources such as AC reactor,

controller, braking unit and contactor.

Area D

: output EMI filter and its cable connection.

Area E

: power spply.

Area F

: motor and its cable.