Shenzhen Hpmont Technology Co., Ltd.

Chapter 7 Troubleshooting and Maintenance

HD3N Series User Manual V1.1

- 101 -

Chapter 7

Troubleshooting and Maintenance

7.1

Troubleshooting

If a fault occurs, the keypad will display the fault alarm status. Meanwhile, faulty relay acts, accordingly

HD3N stops output and the motor coasts to stop.

When fault alarm occurs, user should record the fault in detail and take proper action according to

Table 7-1. If technical help is needed, contact the suppliers or directly call Shenzhen Hpmont

Technology Co., Ltd.

After the fault is eliminated, reset HD3N by any of the following methods:

1. Keypad reset.

2. External reset terminal (DI terminal = No. 16 function).

3. Communication fault reset.

4. Switching on HD3N after completely power off.

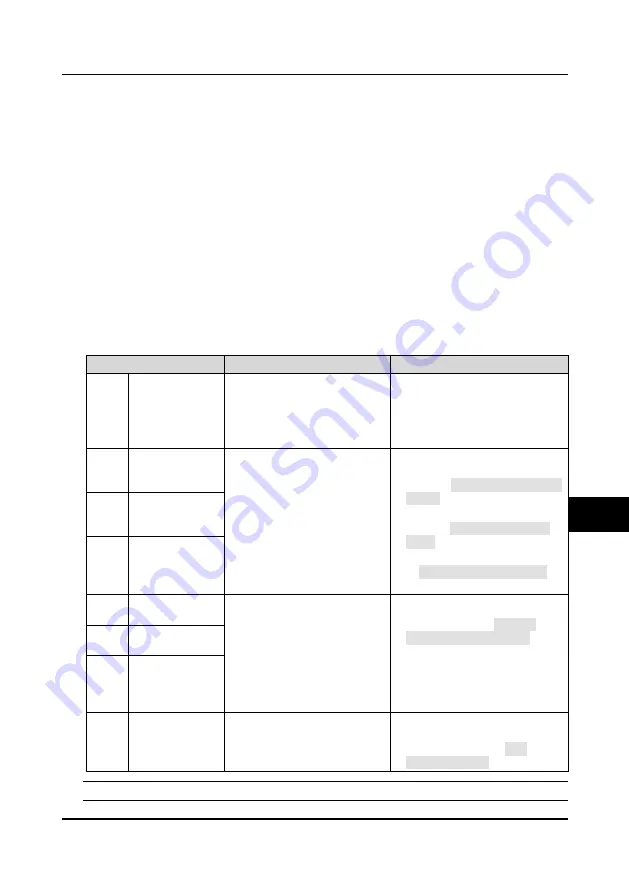

Table 7-1 Fault and counter-measures

Fault

Fault reasons

Counter-measures

-Lu-

DC bus

undervoltage

•

At the begining of power on and at

the end of power off

•

Input voltage is too low

•

Improper wiring leads to

undervoltage of hardware

•

It is normal status of power on and

power off

•

Check input power voltage

•

Check wiring and wire HD3N properly

E0001

Inverter output

overcurrent

(in Acc process)

•

Improper connection between

inverter and motor

•

Improper motor parameters

•

The rating of the used inverter is

too small

•

Acc / Dec time is too short

•

Restart motor that is rotating after

sudden instantaneous voltage loss

•

Did not auto-tune motor in vector

control mode

•

Connect HD3N and motor properly

•

Set correct motor parameter (F08.00 -

F08.04)

•

Select inverter with higher rating

•

Set proper Acc / Dec time (F03.01 -

F03.08)

•

Set F02.00 = 2

•

Do parameter auto-tuning (F08.06)

E0002

Inverter output

overcurrent

(in Dec process)

E0003

Inverter output

overcurrent

(in constant speed

process)

E0004

DC bus over voltage

(in Acc process)

•

Input voltage is too high

•

Deceleration time is too short

•

Improper wiring leads to

overvoltage of hardware

•

Restart motor that is rotating after

sudden instantaneous voltage loss

•

Improper selection of the braking

devices

•

Check power input

•

Set a proper value for Dec time

(F03.02, F03.04, F03.06, F03.08)

•

Check wiring and wire HD3N properly

•

Set F02.00 = 2

•

Select recommended braking devices

according to section 8.2.

E0005

DC bus over voltage

(in Dec process)

E0006

DC bus over voltage

(in constant speed

process)

E0007

Stall overvoltage

•

Bus voltage is too high

•

The setting of stall overvoltage is

too low.

•

Check power input or the function of

brake

•

Properly set the value of stall

overvoltage (F19.19)

Note: E0001 - E0003 and E0008can be reset only after reporting to 3s.

7