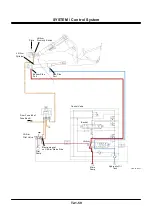

SYSTEM / Control System

T2-1-44

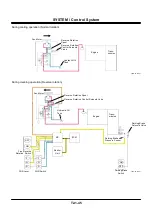

Hydraulic Fan Cleaning Control

Purpose: To clean the radiator and oil cooler by re-

versing the hydraulic fan in order to blow

away dust in case cleaning of the radiator

and oil cooler are needed.

Operation:

1. When the engine is started after the following

conditions exist and the fan reverse rotation

switch is turned ON, the signal is transmitted from

MC to the reverse rotation control solenoid valve.

2. When the reverse rotation control solenoid valve

is operated, the reverse rotation spool is shifted,

and the fan motor rotation is reversed.

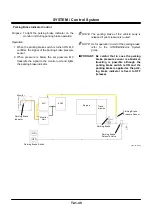

3. In reverse rotation, as hydraulic fan cooling con-

trol is not made, the fan speed changes from

maximum to minimum in response to the de-

pressing amount of the accelerator pedal.

4. In case any one of the following conditions are

changed during reverse rotation, the engine

speed is immediately fixed to idle speed.

5. Hydraulic fan cleaning control is not released only

by turning the fan reverse rotation switch OFF.

This control is released by the procedure of turn-

ing the fan reverse rotation switch OFF – turning

the key switch OFF – turning the key switch ON.

6. In case the engine speed is fixed to idle speed,

this control is released by the procedure of turning

the fan reverse rotation switch OFF – turning the

key switch OFF – turning the key switch ON.

Conditions:

•

Fan reverse rotation switch: ON

•

Parking brake switch: ON (Brake is effective.)

•

FNR lever: neutral

•

FNR switch: neutral

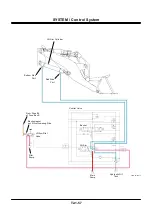

NOTE: Temporarily turn the reverse rotation control

solenoid valve ON when the key switch is

turned ON as the spool maybe stuck in

case the reverse rotation control solenoid

valve is not operated for a long time. It is

turned ON once every one minute after the

key switch is turned ON. This operation is

not made during the hydraulic fan cleaning

control.

Summary of Contents for ZW180

Page 1: ......

Page 2: ......

Page 8: ...4GDT 1 2 Blank ...

Page 10: ...GENERAL Specification T1 1 2 Blank ...

Page 38: ...GENERAL Component Specifications T1 3 14 Blank ...

Page 39: ...MEMO ...

Page 40: ...MEMO ...

Page 42: ...4GDT 2 2 Blank ...

Page 56: ...SYSTEM Control System T2 1 14 Blank ...

Page 82: ...SYSTEM Control System T2 1 40 Blank ...

Page 92: ...SYSTEM Control System T2 1 50 Blank ...

Page 106: ...SYSTEM Control System T2 1 64 Blank ...

Page 116: ...SYSTEM ECM System T2 2 10 Blank ...

Page 128: ...SYSTEM Hydraulic System T2 3 12 Blank ...

Page 147: ...SYSTEM Hydraulic System T2 3 31 Blank ...

Page 150: ...SYSTEM Hydraulic System T2 3 34 Blank ...

Page 184: ...SYSTEM Electric System T2 4 34 Blank ...

Page 185: ...MEMO ...

Page 186: ...MEMO ...

Page 195: ...COMPONENT OPERATION Pump Device T3 1 7 Blank ...

Page 212: ...COMPONENT OPERATION Control Valve T3 2 4 T4GB 03 02 003 1 2 3 4 5 7 8 9 10 11 7 6 ...

Page 214: ...COMPONENT OPERATION Control Valve T3 2 6 T4GB 03 02 003 1 2 3 4 5 7 8 9 10 11 7 6 ...

Page 226: ...COMPONENT OPERATION Control Valve T3 2 18 Blank ...

Page 232: ...COMPONENT OPERATION Control Valve T3 2 24 Blank ...

Page 248: ...COMPONENT OPERATION Steering Pilot Valve T3 4 6 Blank ...

Page 258: ...COMPONENT OPERATION Steering Valve T3 5 10 Blank ...

Page 274: ...COMPONENT OPERATION Pilot Valve T3 6 16 Blank ...

Page 282: ...COMPONENT OPERATION Pilot Valve T3 6 24 Blank ...

Page 299: ...COMPONENT OPERATION Ride Control Valve T3 8 5 Blank ...

Page 306: ...COMPONENT OPERATION Ride Control Valve T3 8 12 Blank ...

Page 348: ...COMPONENT OPERATION Drive Unit T3 9 42 Blank ...

Page 371: ...MEMO ...

Page 372: ...MEMO ...

Page 374: ......