en

Rev. 03 / 02.2021

AB3200

32 / 88

Operation

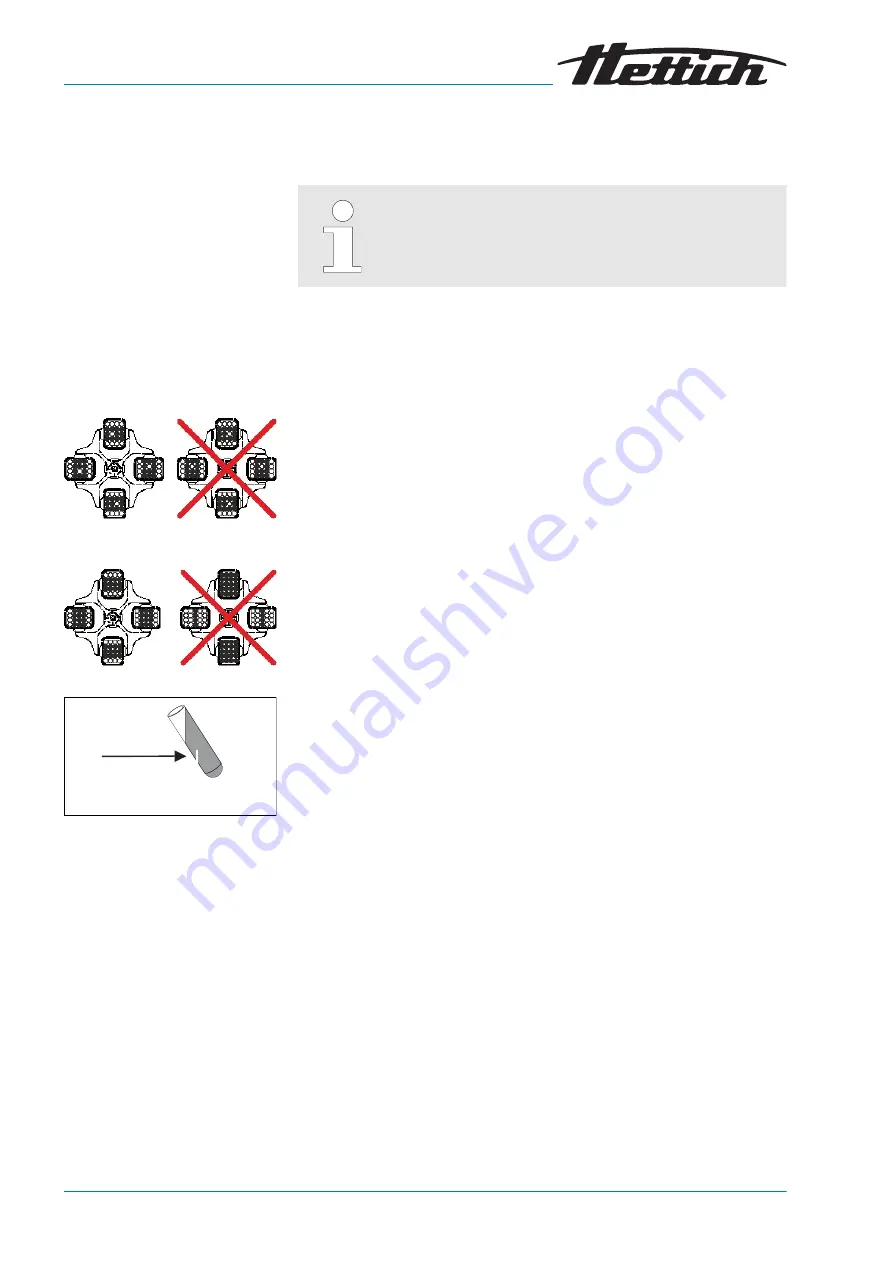

Fig. 14: Rotor is loaded

symmetrically.

Fig. 15: Rotor is evenly loaded

1

2

1 Centrifugal force

2 Liquid

6.5

Loading the rotor

6.5.1

Loading a rotor for classical centrifugation

Standard centrifuge containers made of glass can be

stressed up to RZB 4000 (DIN 58970 Part 2).

■

Check the rotor to make sure it is seated firmly.

■

For swing-out rotors, all rotor places must be occupied with the same

hangers. Certain hangers are labelled with the number of the rotor place.

These hangers may only be used in the corresponding rotor place.

Hangers which are labelled with a set number, e.g. S001/4, may only be

used in a set.

■

The rotors and hangers may only be loaded symmetrically. The centri-

fuge containers must be distributed evenly over all rotor places. For per-

missible combinations, see

Appendix A ‘Rotors and accessories’

on page 86. In the case of angle rotors, all possible places of the rotor

must be loaded. See

Appendix A ‘Rotors and accessories’

■

On certain hangers, the weight of the maximum load or the weight of the

maximum load and the maximum weight of the completely loaded

hanger is specified. These weights must not be exceeded. The weight

specification of the maximum load includes the total weight of the

reducing adapter, frame, centrifuge container and contents.

■

For containers with rubber inlays, there must always be the same

number of rubber inlays under the centrifuge containers.

■

The centrifuge containers may only be filled outside of the centrifuge.

■

The maximum filling amount of the centrifuge containers specified by the

manufacturer must not be exceeded.

In the case of angle rotors, the centrifuge containers may only be filled

such that no liquid can be hurled out of the containers during the centri-

fugation run.

■

When loading the angle rotors, no liquid may enter them or the centri-

fuge chamber.

■

When loading the hangers of the swing-out rotors and when swinging

out the hangers during the centrifugation run, no liquid may get into the

hangers or centrifuge chamber.

■

To keep the weight differences inside the centrifuge containers to a min-

imum, make sure the filling amount in the containers is even.