Page 15

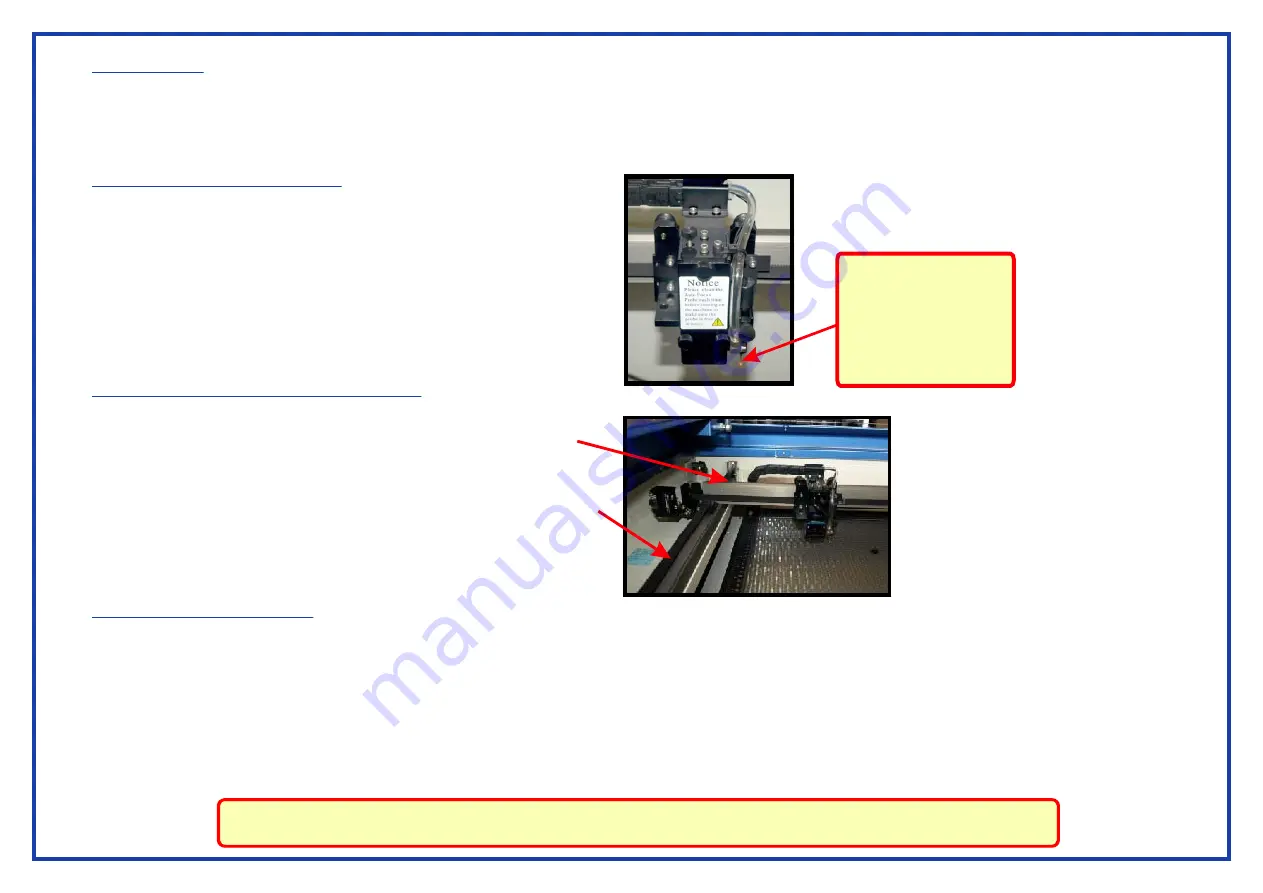

Auto Focus Guage -

ensure the brass

plunger has free

movement and is clean

by gently pushing the

plunger upwards and

seeing if it springs back.

The lens should be checked often and cleaned, possibly hourly especially if you are processing materials which contain resin such as woods, MDF and ply.

Squeeze some lens cleaning fluid onto a cotton swab and gently rub in a spiral motion from the centre outwards on both sides of the lens.

If necessary dry the lens with a clean dry swab. If the lens is not totally clean then instead of the laser light transmitting through the lens it can heat up the glass and

cause expensive damage.

Clean this

every

time the machine is used by wiping the brass plunger

with a cloth to ensure it is free to move up and down.

The gantry arm, motion system track and V shaped carriage wheels

need to be wiped with a clean dry cloth daily to ensure smooth movement

of the laser head.

If you notice a build up of dirt within the wheels then you can simply insert

a cotton bud into the groove of the wheel/gantry and manually move

the head back and forth to clean out the dust particles.

DO NOT apply grease or oil to the motion system tracks.

The grid bed (cutting table) will over time take on a black stained appearance around the area most used for cutting. In most cases this will be localised around the top

left hand quarter. You may also find that you will start to get an odour from the machine itself during and after processing. We have found

from experience that the following procedure does dramatically clean up the grid bed, but the process may need to be repeated to get a good results.

Step 1

: Obtain a trough big enough to accept the grid bed, which is water tight or (use bricks and a sheet of plastic, outdoors).

Step 2

: Dissolve mild detergent into warm water in your trough.

Step 3

: Place the grid bed face down (so that the rubber feet are sticking out of the water) and leave to soak for 24 hours (or preferably a weekend).

Step 4

: Thoroughly dry off the grid bed before use. You may have to repeat a couple of times to get rid of the majority of the staining.

Disclaimer: WF-Education can take no responsibility for any damage to the grid bed.

Degradation of rulers and paintwork will ensue if using detergents and other fluids to clean the cutting surface.

Cleaning the Laser Grid Bed

Cleaning the Gantry Arm & System Tracks

Cleaning the Auto Focus Gauge

Lens Cleaning