Service Manual MCC Cold US 20220700

Page 27

2

Doc. nr.

9124590

Rev.

0

Registration form.

MCC Drop in Unpack instruction

Remove short sides first (Left and Right), by unscrewing them.

Next, remove front and back panel, they are also screwed onto the support beams under the

unit.

Keep the support beams for further use.

Summary of Contents for MCC 120

Page 4: ...Page 4 Service Manual MCC Cold US 20220700...

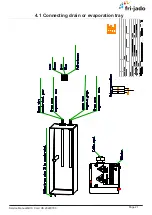

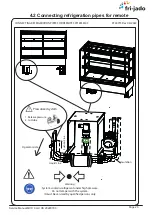

Page 20: ...Page 20 Service Manual MCC Cold US 20220700 4 1 Connecting drain or evaporation tray...

Page 21: ...Service Manual MCC Cold US 20220700 Page 21 4 1 Connecting drain or evaporation tray...

Page 30: ...Page 30 Service Manual MCC Cold US 20220700 5 1 MCC 90 Drop in Dimensions Self Serve...

Page 39: ...Service Manual MCC Cold US 20220700 Page 39 6 0 Installation Front door section first version...

Page 83: ...Service Manual MCC Cold US 20220700 Page 83...

Page 87: ...Service Manual MCC Cold US 20220700 Page 87...

Page 89: ...Service Manual MCC Cold US 20220700 Page 89 Page intentionally left blanc...

Page 102: ...Page 102 Service Manual MCC Cold US 20220700 13 0 Electrical schematics MCC Cold first version...

Page 104: ...Page 104 Service Manual MCC Cold US 20220700 13 2 Electrical wiring MCC Cold Self Serve N L...