1

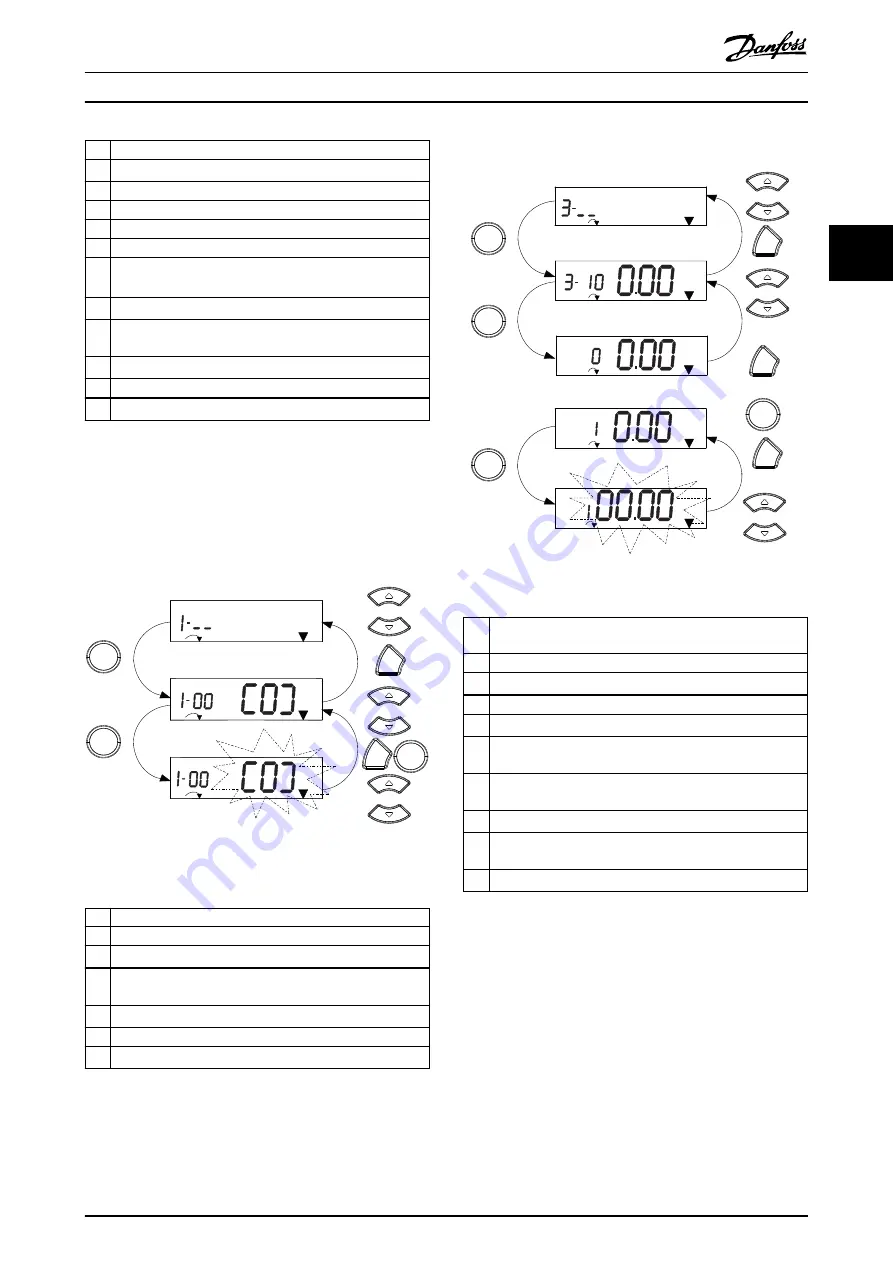

[OK]: The first parameter in the group is shown.

2

Press [

▼

] repeatedly to move down to the parameter.

3

Press [OK] to start editing.

4

[

►

]: First digit flashing (can be edited).

5

[

►

]: Second digit flashing (can be edited).

6

[

►

]: Third digit flashing (can be edited).

7

[

▼

]: Decreases the parameter value, the decimal point

changes automatically.

8

[

▲

]: Increases the parameter value.

9

[Back]: Cancel changes, return to 2.

[OK]: Accept changes, return to 2.

10 [

▲

][

▼

]: Select parameter within the group.

11 [Back]: Removes the value and shows the parameter group.

12 [

▲

][

▼

]: Select group.

Table 3.5 Changing Values in Continuous Parameters

For enumerated parameters, the interaction is similar, but

the parameter value is shown in brackets because of the

digits limitation (4 large digits) on NLCP, and the enum can

be greater than 99. When the enum value is greater than

99, the LCP can only show the first part of the bracket.

130BC447.11

Setup 1

Setup 1

Setup 1

1

2

3

4

5

6

OK

OK

Back

7

OK

Back

Illustration 3.6 Main Menu Interactions - Enumerated

Parameters

1

[OK]: The first parameter in the group is shown.

2

Press [OK] to start editing.

3

[

▲

][

▼

]: Change parameter value (flashing).

4

Press [Back] to cancel changes or [OK] to accept changes

(return to screen 2).

5

[

▲

][

▼

]: Select a parameter within the group.

6

[Back]: Removes the value and shows the parameter group.

7

[

▲

][

▼

]: Select a group.

Table 3.6 Changing Values in Enumerated Parameters

Array parameters function as follows:

130BC448.10

1

2

4

5

6

7

8

9

10

OK

Back

Back

Back

5 x

Setup 1

Setup 1

Setup 1

Setup 1

%

INDEX

%

INDEX

%

INDEX

Setup 1

INDEX

%

OK

OK

OK

Illustration 3.7 Main Menu Interactions - Array Parameters

1

[OK]: Shows parameter numbers and the value in the first

index.

2

[OK]: Index can be selected.

3

[

▲

][

▼

]: Select index.

4

[OK]: Value can be edited.

5

[

▲

][

▼

]: Change parameter value (flashing).

6

[Back]: Cancels changes.

[OK]: Accepts changes.

7

[Back]: Cancels editing index, a new parameter can be

selected.

8

[

▲

][

▼

]: Select parameter within the group.

9

[Back]: Removes parameter index value and shows the

parameter group.

10 [

▲

][

▼

]: Select group.

Table 3.7 Changing Values in Array Parameters

Programming

Programming Guide

MG07C102

Danfoss A/S © 12/2015 All rights reserved.

17

3

3