Troubleshooting

ESIE13-02

Part 4 – Troubleshooting

56

3

1

4

5

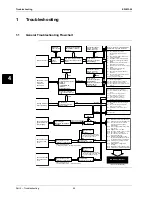

1.2.1

Equipment does not Operate

Applicable model

ERHQ011~016*

ERLQ004~016*

Error detection

method

Error generating

condition

Supposed causes

Fuse blown or disorder of contact in operation circuit

Faulty operation switch or contact point

Faulty high pressure switch

Faulty magnetic switch for fan motor

Activation or fault of overcurrent relay for fan motor

Faulty overcurrent relay for compressor

Faulty compressor protection thermostat

Insufficient insulation in electric system

Faulty contact point of magnetic switch for compressor

Malfunction of compressor

Defective remote controller

Troubleshooting

Caution

Be sure to turn off power switch before connect or disconnect connector, or parts damage may be

occurred.

Is

thermostat changed and

reset again?

Is

operation lamp on

LCD remote controller

flashing?

Is operation

switch pressed

repeatedly?

Is there power

failure?

Is power switch

OFF or fuse for power switch

blown?

Possibly faulty electric

component

Turn on power switch or replace

fuse.

If high-harmonics circuit breaker is

not used on inverter compressor,

have the circuit breaker replaced.

Wait until power returns.

Normal.

Equipment starts operation 3

minutes later (3-min standby).

Diagnose based on error code on

remote controller.

Normal.

Equipment starts operation 3

minutes later (3-min standby).

Check electric system.

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES