ESIE13-02

Additional Checks for Troubleshooting

157

Part 4 – Troubleshooting

4

3

4

5

4

6.7

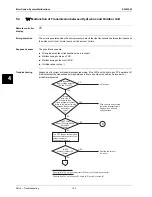

Check No.7 - Evaluation of Abnormal Low Pressure

Abnormally low pressure level is mostly caused by the evaporator side. The following contents are

provided based on field checking of service engineer. Further, the number is listed in the order of

degree of influence.

In cooling operation

In heating operation

Check items (Possible causes)

Judgment

Does the outdoor unit fan run normally?

Visual inspection

Is the hydro-box filter clogged?

Visual inspection

Is there clogging before or after the EV

(capillary)?

Check if there is a temperature difference

before and after EV (capillary).

Check if the main valve unit of EV operates (by

noise, vibration).

Is the check valve clogged?

*Heat pump model only

Check if there is a temperature difference

before and after check valve.

If YES, the check valve is caught.

Is the LPS normal?

Check continuity using a tester.

Is the hydro-box installed under such conditions

that short circuit easily occurs?

Visual inspection

Is the refrigerant gas short?

Conduct refrigerant collection and vacuum

drying, and then add proper amount refrigerant.

Check items (Possible causes)

Judgment

Does the outdoor unit fan run normally?

Visual inspection

Is the outdoor unit heat exchanger clogged?

Visual inspection

Is the outdoor unit installed under such

conditions that short circuit easily occurs?

Visual inspection

Is there clogging before or after the EV

(capillary)?

Check if there is a temperature difference

before and after EV (capillary).

Check if the main valve unit of EV operates (by

noise, vibration).

Is the check valve clogged?

Check if there is a temperature difference

before and after check valve.

If YES, the check valve is caught.

Is the LPS normal?

Check continuity using a tester.

Is the refrigerant gas short?

Conduct refrigerant collection and vacuum

drying, and then add proper amount refrigerant.