Performance Verification

7-4

Service Manual

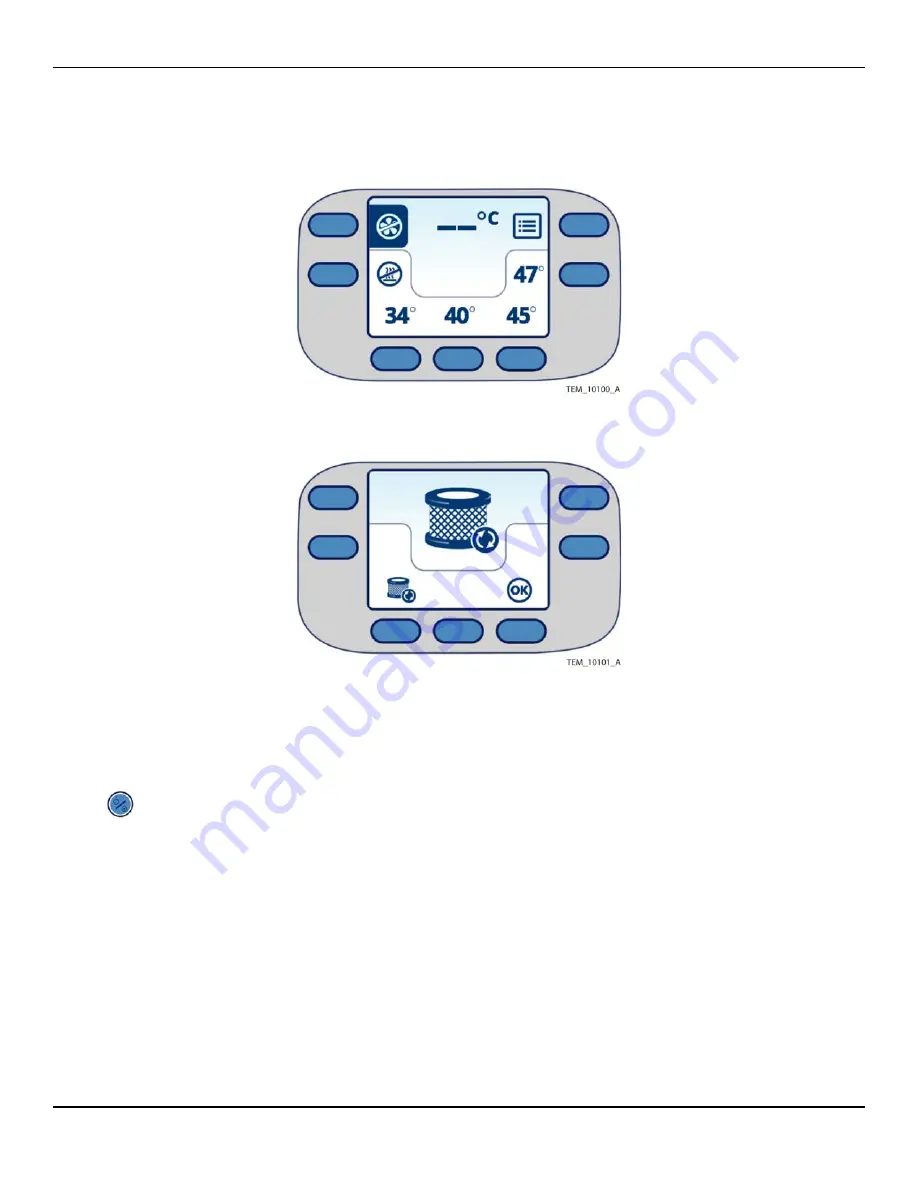

Figure 7-2.

Main Screen at Power-On

Figure 7-3.

Replace Filter Screen at Power-On

3.

Press one of the temperature keys. Verify that the temperature reading on the

screen rises and stabilizes.

4.

When finished with all testing:

a.

Press the

On/Standby

key to power off the unit.

b.

Unplug the unit from the outlet.

Power-On Test Failure

If the test fails, see

Summary of Contents for WarmTouch

Page 1: ...Service Manual WarmTouch Convective Warming Unit...

Page 8: ...Page Left Intentionally Blank vi Service Manual...

Page 32: ...Page Left Intentionally Blank 1 18 Service Manual Introduction...

Page 42: ...Installation 3 4 Service Manual Figure 3 3 Power Cord Wrapped and Secured...

Page 45: ...Installing the Warming Unit Service Manual 3 7 Figure 3 5 Warming Unit Mounted on IV Pole...

Page 49: ...Installing the Warming Unit Service Manual 3 11 Figure 3 9 Warming Unit Mounted on Cart...

Page 50: ...Page Left Intentionally Blank 3 12 Service Manual Installation...

Page 70: ...Page Left Intentionally Blank 5 12 Service Manual Maintenance...

Page 84: ...Page Left Intentionally Blank 6 14 Service Manual Troubleshooting...

Page 105: ...Power Cord Replacement Service Manual 8 7 Figure 8 5 Power Cord Wrapped and Secured...

Page 118: ...Page Left Intentionally Blank 9 8 Service Manual Accessing the Inside of the Warming Unit...

Page 246: ...Enclosure Replacement 12 14 Service Manual Figure 12 10 Power Cord Wrapped and Secured...

Page 266: ...Page Left Intentionally Blank 12 34 Service Manual Enclosure Replacement...

Page 274: ...Page Left Intentionally Blank 13 8 Service Manual Product Specifications...

Page 313: ......