Manuale/Manual/Manuel/Handbuch/Manual

–

07/2014

Pagina

43

N.B.:

if

the

tyre

permits

it,

the

operation

described

above

can

be

speeded

up

by

mounting

both

beads

at

the

same

time:

Follow

the

steps

described

under

points

1

‐

5

described

above

but

instead

of

attaching

the

clip

to

just

the

first

bead

(refer

to

point

5),

clip

it

to

both.

Lift

the

rim

with

the

tyre

hooked

to

it

and

turn

it

anticlockwise

15

‐

20

cm

(clip

at

10

o’clock).

Follow

the

steps

described

in

points

12

‐

18

above.

Mounting

with

the

hooked

tool

1.

Follow

the

steps

described

in

points

1

‐

6

for

mounting

with

the

disk.

2.

Move

the

tool

carrier

arm

to

its

non

‐

working

position.

Move

it

to

the

inside

plane

of

the

tyre

and

rehook

it

at

this

position.

3.

Check

to

make

sure

the

hook

tool

is

positioned

on

the

wheel

side.

If

not,

press

lever

and

turn

it

180°.

4.

Take

the

mobile

control

unit

to

work

position

D.

5.

Move

the

tool

forward

until

the

red

reference

dot

is

lined

up

with

the

outside

edge

of

the

rim

and

about

5

mm

from

it

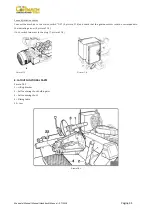

(See

picture

F13.16).

Picture

F13.16

6.

Take

the

mobile

control

unit

to

work

position

C.

7.

Move

to

the

outside

of

the

wheel

and

check

the

exact

position

of

the

hook

visually

and

adjust

it

as

needed.

Then

turn

the

spindle

clockwise

until

the

clip

is

at

the

bottom

(6

o’clock).

The

first

bead

will

be

on

the

rim.

8.

Remove

the

clip.

9.

Take

the

mobile

control

unit

to

work

position

D.

10.

Remove

the

tool

from

the

tyre.

11.

Move

the

tool

carrier

arm

to

its

non

‐

working

position;

move

it

to

the

outside

plane

of

the

tyre

and

rehook

it

in

this

position.

12.

Turn

the

tool

180°

with

lever.

13.

Attach

the

clip

at

the

bottom

(6

o’clock)

outside

the

second

bead.

14.

Take

the

mobile

control

unit

to

work

position

C.

15.

Turn

the

spindle

clockwise

to

about

90°

(clip

at

9

o’clock).

16.

Bring

the

tool

forward

until

the

red

reference

dot

is

lined

up

with

the

outside

edge

of

the

rim

and

about

5

mm

from

it.

Begin

to

turn

the

spindle

clockwise

and

check

if,

after

about

90°,

of

rotation

the

second

bead

has

started

to

slip

into

the

center

well.

Continue

turning

until

the

clip

is

at

the

bottom

(6

o’clock).

The

second

bead

will

now

be

mounted

on

the

rim.

17.

Follow

the

steps

described

in

points

13

‐

18

for

mounting

with

the

disk

since

this

will

ensure

that

the

wheel

is

removed

correctly

from

the

machine.

13.3

Tubed

wheels

Bead

breaking

Unscrew

the

bush

which

fixes

the

valve

when

deflating

the

tyre

so

that

the

valve,

coming

in

the

inside

of

the

rim,

is

not

an

obstacle

during

bead

breaking.

Summary of Contents for FT 26S

Page 2: ......

Page 6: ......

Page 33: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 27 19 SCHEMA ELETTRICO...

Page 34: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 28 20 SCHEMA IDRAULICO...

Page 35: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 29...

Page 61: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 55 19 ELECTRICAL DIAGRAM...

Page 62: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 56 20 HYDRAULIC DIAGRAM...

Page 63: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 57...

Page 89: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 83 19 SCHEMA ELECTRIQUE...

Page 90: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 84 20 SCHEMA HYDRAULIQUE...