Manuale/Manual/Manuel/Handbuch/Manual

–

07/2014

Pagina

49

8.

Move

the

tool

holder

arm

away

from

the

rim

edge.

Release

the

ratchet

and

lift

the

arm

to

the

non

‐

working

position.

Move

the

tool

holder

arm

to

the

inner

side

of

the

wheel.

9.

Press

the

tool

rotation

lever

and

turn

it

180°;

the

tool

will

automatically

lock.

Lower

the

arm

to

the

working

position.

10.

Take

the

mobile

control

unit

to

work

position

D.

11.

Turn

the

turntable

and

lower

it

at

the

same

time

in

order

to

insert

the

bead

breaker

disk

between

the

bead

and

the

rim

edge.

Only

when

the

bead

starts

to

detach,

move

the

disk

forward

until

positioning

the

external

bead

flush

with

the

external

rim

edge.

N.B.:

lubricate

during

this

operation.

12.

Tilt

the

tool

holder

arm

to

the

non

‐

working

position.

13.

Take

the

mobile

control

unit

to

work

position

B.

14.

Move

the

mobile

platform

directly

under

the

wheel.

15.

Lower

the

turntable

until

the

tyre

rests

on

the

platform.

16.

Move

the

platform

outward

until

the

tyre

(with

the

attached

side

ring)

comes

off

the

rim.

17.

Remove

the

rim

from

the

turntable.

18.

Position

the

tyre

on

the

platform

with

the

side

ring

turned

towards

the

turntable.

19.

Clamp

the

side

ring

on

the

turntable

as

described

for

“WHEEL

CLAMPING”.

The

tyre

is

not

fastened

securely

to

side

ring.

Any

strain

on

it

during

positioning

and/or

clamping

could

cause

it

to

detach

and

fall.

20.

Take

the

mobile

control

unit

to

work

position

D.

21.

Lift

the

wheel.

22.

Return

the

tool

holder

arm

to

the

working

position.

23.

Position

the

turntable

so

the

bead

breaker

disk

is

perfectly

lined

up

with

the

tyre

bead.

24.

Turn

the

turntable

and

at

the

same

time

move

the

bead

breaker

disk

forward

until

the

tyre

exits

the

side

ring

completely.

When

the

beads

come

off

the

rim,

the

tyre

will

fall.

Make

sure

that

no

one

is

accidentally

located

in

the

work

area.

Mounting

Wheels

with

3

–

piece

side

rings

1.

Move

the

turntable

arm

to

the

non

‐

working

position.

If

the

rim

has

been

removed

from

the

turntable,

reclamp

it

as

described

in

the

“WHEEL

CLAMPING”

paragraph.

N.B.:

if

the

wheel

has

an

inner

tube,

position

the

rim

with

the

valve

slot

at

the

bottom

(6

o’clock).

2.

Lubricate

the

tyre

beads

and

rim

using

the

recommended

soapy

solution.

3.

Take

the

mobile

control

unit

to

work

position

B.

4.

Move

the

mobile

platform

outward

in

order

to

place

the

tyre

on

it.

N.B.:

if

the

wheel

has

an

inner

tube,

position

the

tyre

with

the

valve

at

the

bottom

(6

o’clock).

5.

Lower

or

lift

the

turntable

in

order

to

exactly

center

the

rim

to

the

tyre.

6.

Move

the

platform

inward

to

make

the

rim

enter

the

tyre.

N.B.:

if

the

tyre

has

an

inner

tube,

push

the

valve

inside

so

it

will

not

be

damaged.

Move

forward

with

the

platform

until

the

rim

is

completely

inserted

in

the

tyre.

7.

Move

the

tool

holder

arm

to

the

external

side

then

lower

it

to

the

working

position

with

the

bead

breaker

disk

turned

towards

the

wheel.

N.B.:

if

the

tyre

is

not

sufficiently

inserted

on

the

rim,

move

the

turntable

until

the

tyre

bead

is

positioned

in

correspondence

of

the

bead

breaker

disk.

Move

the

disk

forward

(and

at

the

same

time

turn

the

turntable)

until

it

is

completely

inserted.

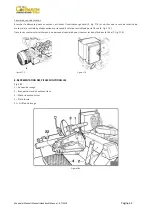

8.

Put

the

side

ring

on

the

rim

and

then

install

the

locking

ring

with

the

help

of

the

bead

breaker

disk

as

shown

in

picture

F13.27.

Summary of Contents for FT 26S

Page 2: ......

Page 6: ......

Page 33: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 27 19 SCHEMA ELETTRICO...

Page 34: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 28 20 SCHEMA IDRAULICO...

Page 35: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 29...

Page 61: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 55 19 ELECTRICAL DIAGRAM...

Page 62: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 56 20 HYDRAULIC DIAGRAM...

Page 63: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 57...

Page 89: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 83 19 SCHEMA ELECTRIQUE...

Page 90: ...Manuale Manual Manuel Handbuch Manual 07 2014 Pagina 84 20 SCHEMA HYDRAULIQUE...