62-11640

8–10

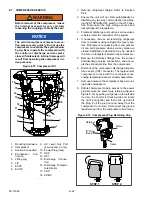

Figure 8.10 Fuel Level Sensor

1. Fuel Level Sensor

2. Gasket

3. Focus Tube

4. Sensor Flange

5. Fuel Level Sensor Flange

6. Fuel Tank

7. Wire FLSC to 2MM-13 (Connection C)

8. Wire FLSB to 2MM-24 (Connection B)

9. Wire PCM-22 to FLSA (Connection A)

10. White Wire (Connection C)

11. Black Wire (Connection B)

12. Red Wire (Connection A)

13. Ground (Shield)

14. Yellow Wire (Connection C)

15. Black Wire (Connection B)

16. Red Wire (Connection A)

17. Wires From Sensor

- - - - -

NOTICE

Torque fuel level sensor mounting

screws to 15 to 18 inch/lbs (1.7 to 2.0

Nm). DO NOT over tighten, as little as 20

inch/pounds (2.3 Nm) will damage the

sensor.

1. Using new gaskets, reinstall fuel level sensor

components. The mounting holes are not sym-

metrical, there is an alignment hole in the sen-

sor, alignment holes and index dimples in the

gaskets and an alignment notch in the focus

tube flange to assist in aligning the components.

Install mounting screws and washers in all

mounting holes and bring to finger tight. Tighten

in accordance with the instructions provided in

the preceding CAUTION.

2. With the fuel tank empty the output reading

should be approximately 0.25 VDC.

3. With the fuel tank full, the output reading should

be approximately 4.75 VDC.

4. Start unit and check for leaks.

8.5.8

Fuel Heater

The optional fuel heater (

) applies heat to

fuel in the fuel filter. Heating the fuel dissolves/prevents

paraffin wax crystals (and ice) that form when diesel

fuel is chilled thus enabling the water separator to work

more efficiently and to prevent the filter from plugging

with wax and/or ice crystals. When the ambient air sen-

sor is reading 77°F (25°C) or higher, the control system

will not enable this circuit.

Also, the heater is fitted with an internal temperature

switch (FHTS - see schematic diagram,

).

The heater used in spin on type filter systems closes

on a temperature fall to energize the heater element at

temperatures below 45°F (7.2°C), and opens on a tem-

perature rise to de-energize the heater element at 75°F

(23.9°C). The heater used in suction side filter systems

closes at temperatures below 537°F (11.73.9°C).

To Test the Fuel Heater:

), check to

ensure the Ambient Air Temperature reading is

below 77°F (25°C), if the reading is below this

temperature the fuel heater relay (FHR) should

be energized. If the relay does not energize,

check for power from PCM fuse F10 to the relay

coil + terminal and ground from the coil negative

connection through PCM-17 to 3MM-17.

2. With the relay contacts closed, check for power

from F7, through the relay contacts, fuse F14,

through PCM-14 & 3 through SP25 to the fuel

heater connector at terminal A. Also check for

ground from the fuel heater connector terminal

B through SP10 to GND1RING1.

3. If the wiring is good and the fuel heater tempera-

ture is below the cut in temperature replace the

fuel heater. If the wiring is good but the fuel

heater temperature is above the cut out tem-

perature, the internal temperature switch may

be open. Retest at a temperature below the

switch close point as soon as conditions allow.

4. Start unit and check for leaks.

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......