8–13

62-11640

To Start the Rack Position Sensor Calibration Proce-

dure:

1. Put the system into Technician Mode, refer to

2. Select the Component Calibration Mode Soft

key.

3. Press “=” to start the Rack Position Sensor cali-

bration.

During the calibration process, the display will show the

Engine Load %, RPMs, current calibration offset (the

offset in the Engine ECU), and calibration status.

The Rack Position Sensor is calibrated at an engine

speed of 1700

−

1780 RPM. In order to reach the

required engine speed, the system will incrementally

increase engine load in the following order:

Low Speed

−

Compressor Start

−

High Speed

−

Heater

1 On – Heater 2 On – (3 minutes) – Economized Mode.

If, after placing the system in Economized Mode for

180 seconds, engine speed is not high enough to cali-

brate the sensor (1700 – 1780 RPM), the system will

indicate that the load is too low for calibration. In this

case you will have to manually increase the system

load by blocking the condenser coil. Once the load is

increased enough for the engine to reach calibration

RPM, the calibration should complete successfully.

After the calibration process is finished, the system will

indicate that the calibration was successful, and the

engine will shut down.

8.5.14

Cooling System

a. Cleaning and Flushing:

Air flows through the condenser and then the radiator.

The cooling surfaces must be clean and the interior of

the radiator must be clean for adequate cooling.

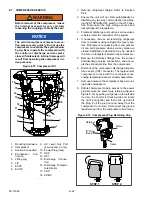

NOTICE

Use only ethylene glycol anti-freeze (with

inhibitors) in system as glycol by itself

will damage the cooling system. Always

add pre-mixed 50/50 anti-freeze and water

to radiator/ engine. Never exceed more

than a 60% concentration of anti-freeze.

Use Texaco Havoline extended life cool-

ant or any other extended life coolant

which is Dexcool approved and has 5/150

(5 years/150,000 miles) on the label.

1. Ensure the unit will not start automatically by

disabling any two way communication and plac-

ing the STOP/RUN-OFF switch in the OFF posi-

tion. Disconnect the high voltage source and

lockout/tagout the receptacle.

2. Remove all foreign material from the condenser

& radiator by reversing the normal air flow. (Air

is pulled in through the front and discharges

over the engine.) Compressed air or water may

be used as a cleaning agent.

WARNING

!

Do not remove the cap from a hot coolant

system; if the cap must be removed, do

so very slowly in order to release the

pressure without spray.

NOTE

Draining the coolant from the engine petcock

will leave approximately 1 quart (.9 liters) of

coolant in the block.

3. Drain coolant into suitable container by remov-

ing coolant bottle cap and the engine drain plug.

NOTICE

NEVER POUR COLD WATER INTO A HOT

ENGINE, however hot water can always

be added to a cold engine.

4. Install hose or drain plug and fill system with

clean, untreated water.

NOTE

Only clean water should be used to flush the

cooling system. Do not use any radiator

flush or detergents to clean the radiator.

5. Start the engine and drain system while warm.

Rinse system three times after it has cooled

down. Refill system with water.

6. Run engine to operating temperature. Drain sys-

tem again and fill with 50/50 water/anti-freeze

mixture. (refer to the Caution Note at the begin-

ning of this section.)

7. Start unit and check for leaks.

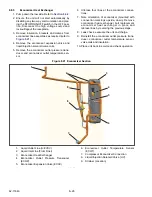

b. Radiator Replacement:

1. Ensure the unit will not start automatically by

disabling any two way communication and plac-

ing the STOP/RUN-OFF switch in the OFF posi-

tion. Disconnect the high voltage source and

lockout/tagout the receptacle.

2. Drain coolant into a suitable container by remov-

ing coolant bottle cap and the engine drain plug.

3. Remove condenser fans, refer to

. When removing the road side fan

assembly, remove the condenser to subcooler

line support bracket completely, to allow clear-

ance for coil removal.

4. Remove the radiator frame assembly mounting

bolts (see

frame assembly.

5. Remove top radiator mounting brackets and

remove the radiator through the top of the unit.

6. Re-assemble in reverse order of removal.

7. Flush and fill radiator with coolant. (Refer to

Summary of Contents for Vector 8500

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

Page 24: ...1 7 62 11640 62 03958 ...

Page 25: ...62 11640 1 8 ...

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......