Chapter 11

11-2

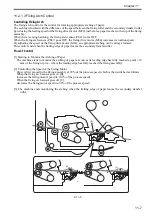

11.1.2 Major Components

T-11-2

Ref.

Component

Notation

Description

[A] Fixing Belt Unit

[1]

Fixing belt

50 mm dia.

[2]

Fixing roller

center: 18.5 mm dia.

ends: 18 mm dia.

[3]

Fixing belt tension roller

center: 22 mm dia.

ends: 21.5 mm dia.

[4]

Fixing main thermistor

TH1

contact type (temperature control, overheating

detection)

[5]

Fixing sub thermistor 1

TH2

contact type (overheating detection)

[6]

Fixing sub thermistor 2

TH3

contact type (overheating detection)

[7]

Fixing thermal switch

TP1

contact type

[8]

Fixing pad

nip area formation

[9]

Fixing cleaning felt

prevents intrusion of dust between fixing belt and

sliding sheet

[10]

Fixing sliding sheet

limits wear on Fixing belt and Fixing pad

[B] Pressure Belt Unit

[11]

Pressure belt

50 mm dia.

[12]

Pressure roller

center: 23.5 mm dia.

ends: 18.5 mm dia.

[13]

Pressure belt tension roller

center: 21.5 mm dia.

ends: 18.5 mm dia.

[14]

Pressure heater

H1

halogen heater: 300 W

[15]

Pressure main thermistor

TH4

non-contact type (temperature control, overheating

detection)

[16]

Pressure sub thermistor

TH5

contact type (overheating detection)

[17]

Pressure sub thermistor 2

TH6

contact type (overheating detection)

[18]

Pressure thermal switch

TP3

non-contact type

[19]

Pressure pad

forms nip area

[20]

Pressure belt oil applying felt

prevents wear on pressure belt

[21]

Oil collecting felt

prevents oil from reaching belt surface

[22]

Pressure sliding sheet

limits wear on pressure belt and pressure pad

[C] IH unit

[23]

IH coil

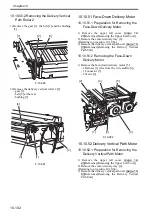

[D] Fixing Drive System

[24]

Fixing motor

M24

controls fixing/pressure

[25]

Fixing belt displacement

control motor

M28

controls displacement of fixing belt

[26]

Pressure belt displacement

control motor

M29

controls displacement of pressure belt

Summary of Contents for Color imageRUNNER C5180 Series

Page 22: ...Chapter 1 INTRODUCTION...

Page 64: ...Chapter 2 INSTALLATION...

Page 110: ...Chapter 3 BASIC OPERATION...

Page 119: ...Chapter 4 BASIC OPERATIONS AS A PRINTER...

Page 129: ...Chapter 5 MAIN CONTROLLER...

Page 138: ...Chapter 5 5 8 F 5 8 CPU HDD ROM access to the program at time of execution...

Page 165: ...Chapter 6 ORIGINAL EXPOSURE SYSTEM...

Page 209: ...Chapter 7 IMAGE PROCESSING SYSTEM...

Page 212: ...Chapter LASER EXPOSURE 8...

Page 239: ...Chapter 9 IMAGE FORMATION...

Page 324: ...Chapter 10 PICKUP FEEDING SYSTEM...

Page 435: ...Chapter 11 FIXING SYSTEM...

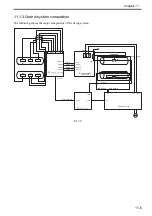

Page 460: ...Chapter 11 11 23 F 11 13 SEN3 SEN2 SEN1 SEN2 SEN3 SEN1 SEN2 SEN3 SEN1...

Page 491: ...Chapter 12 EXTERNALS CONTROLS...

Page 498: ...Chapter 12 12 5 F 12 2 FM1 FM7 FM9 FM2 FM13 FM14 FM12 FM11 FM10 FM5 FM3 FM4 FM8 FM6...

Page 512: ...Chapter 12 12 19 2 Remove the check mark from SNMP Status Enabled F 12 10...

Page 553: ...Chapter 13 MEAP...

Page 557: ...Chapter 14 RDS...

Page 569: ...Chapter 15 MAINTENANCE INSPECTION...

Page 578: ...Chapter 16 STANDARDS ADJUSTMENTS...

Page 597: ...Chapter 17 CORRECTING FAULTY IMAGES...

Page 612: ...Chapter 17 17 14 F 17 7 PLG1 ELCB1 SP1 H4 H3 H2 H1 H1 H2 LA1...

Page 617: ...Chapter 18 SELF DIAGNOSIS...

Page 644: ...Chapter 19 SERVICE MODE...

Page 778: ...Chapter 20 UPGRADING...

Page 823: ...Chapter 21 SERVICE TOOLS...

Page 828: ...APPENDIX...

Page 851: ......