9

Inspection and maintenance

Logano plus GB402 - Subject to technical modifications!

43

9.4

Checking the heating system operating pressure

In sealed unvented systems the pressure gauge needle

must be within the green band.

Ensure that the red pressure gauge needle is set to the

required operating pressure.

B

Check the operating pressure of the heating system.

The operating pressure is too low if the pressure gauge

needle is below the green range. Top up with water.

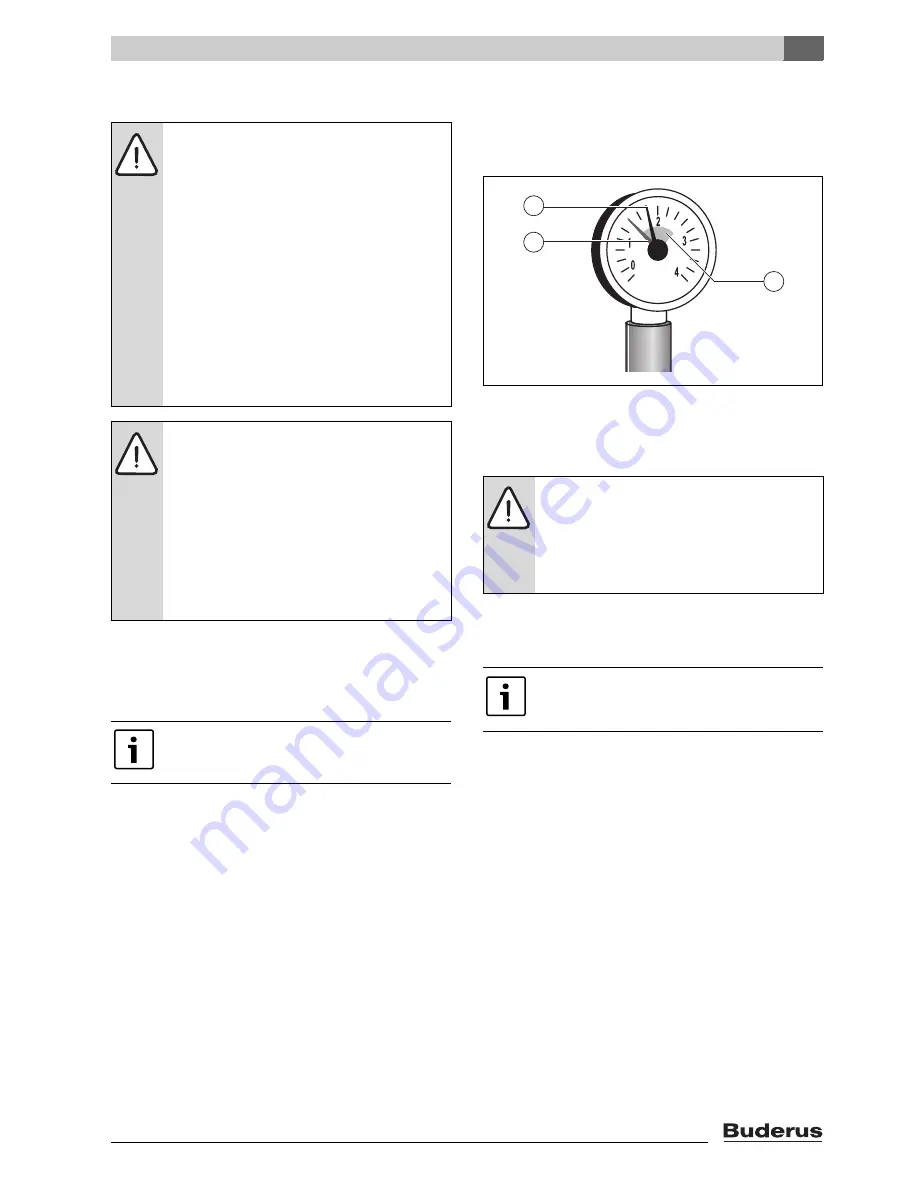

Fig. 42 Pressure gauge for sealed unvented systems

1

Red needle

2

Pressure gauge needle

3

Green band

B

Fill water via the on-site drain & fill valve.

B

Vent the heating system via the radiator bleed valves.

B

Check the operating pressure again.

B

Enter amount of top-up water in the operator's log.

9.5

Measuring carbon dioxide content

B

Insert the test sensor through the test port in the flue

pipe and hold it in the core gas flow.

B

Record the flue gas values.

If the CO

2

content differs by more than 0.5 % from its

set value (

Æ

Tab. 3, page 11), adjust the burner as

described from Chapter 7.10 to 7.10.2.

NOTICE:

System damage.

If the heating system is filled when hot, the

resulting temperature stresses can cause

stress cracks. The boiler will then leak.

B

Only fill the heating system when cold

(the flow temperature should not exceed

40 °C).

B

When the heating system is in

operation, never fill it via the boiler

drain & fill valve. Instead, only use the

filling valve in the heating system

pipework (return).

B

Pay attention to the water quality as

specified in the operator's log, and record

the volume and quality of fill water used.

NOTICE:

System damage due to frequent

topping up.

Depending on water quality, the heating

system may be damaged by corrosion or

limescale formation if you frequently need to

top up the water (observe the operator's log).

B

Vent the heating system during filling.

B

Check the heating system for leaks.

B

Check the function of the expansion

vessel.

Create an operating pressure of at least

1 bar.

CAUTION:

Health risk from contaminated

drinking water.

B

Observe all regulations and standards

applicable in your country regarding the

prevention of drinking water

contamination.

The operating pressure can also be checked

at the control unit via the “Info menu”

(e.g. display “P1.4” corresponds to 1.4 bar).

6 720 615 876-59.1RS

3

2

1