9

Inspection and maintenance

Logano plus GB402 - Subject to technical modifications!

51

9.9.5

Fitting the ventilation air unit

B

Push on the ventilation air hose together with the

connector onto the ventilation air collector and secure

with a hose clip at the upper adaptor.

9.10 Checking for leaks during operation

B

Start the boiler and check all gaskets for leaks under

full load using a leak detection agent.

B

For further leak checks of the entire gas train, see

Chapter 7.15, page 36.

9.11 Checking the ionisation current

To ensure trouble-free operation, the ionisation current at

partial and full load (and burning flame) should be at least

15 μA.

The ionisation current (flame current) can be read off on

the RC35 programming unit at “SERVICE MENU

DIAGNOSIS/MONITOR VALUE” (

Æ

Chapter 7.14.1).

9.12

Completing inspection and

maintenance

9.12.1 Removing meters

9.12.2 Installing casing parts

B

Fit the casing parts (

Æ

Fig. 37, page 37).

9.12.3 Confirming inspection and service

B

Sign the inspection and maintenance report in this

manual (

Æ

Chapter 9.14).

9.13

Replacing the gaskets subject to

time in use

The following gaskets must be replaced after expiry of the

specified time in use.

NOTICE:

System damage through

contaminated air.

B

Prior to fitting the ventilation air hose,

check the ventilation air grille (integrated

into the lower hose adaptor) for

contamination and clean if required.

NOTICE:

Risk of system damage due to

short circuit.

B

Cover the fan and other areas at risk prior

to commencing the leak detection.

B

Never spray the leak detection agent on

cable entries, plugs or cables. Do not allow

it to drip onto them either.

Observe the instructions for the BC10 and

RC35.

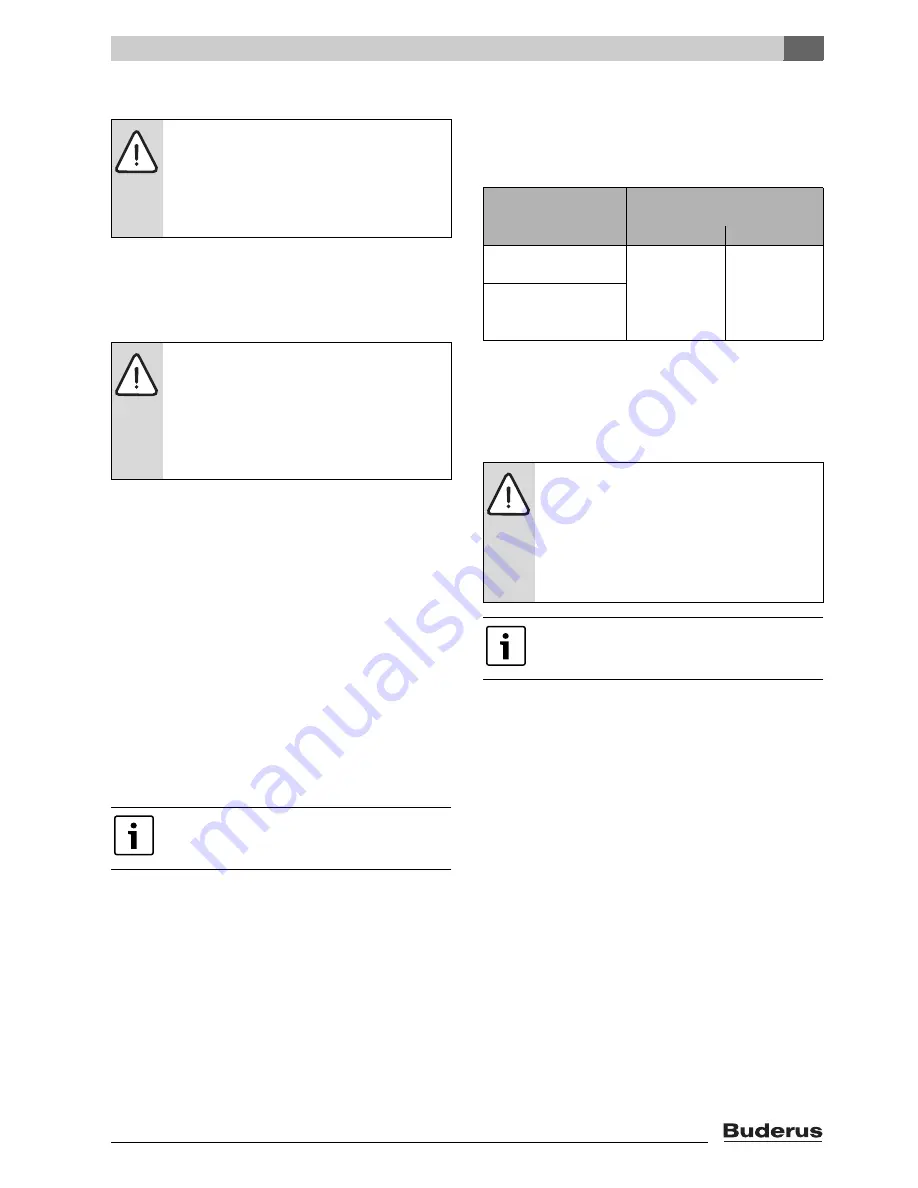

Gasket

Replacement after x years

in use for type of use:

Standard

1)

1) Applicable to all conventional uses of the boiler as a gas

condensing boiler for DHW and central heating.

Industrial

2)

2) Applicable to use of the boiler for industrial heat generation with

constantly high flow temperatures and burner loads, for

example.

Mixture manifold

gasket (O-ring)

after

5 years

after

3 years

Cleaning cover

gasket (on the heat

exchanger)

Tab. 15 Replacement according to time in use

WARNING:

Risk to life from escaping gases!

B

Always replace the electrode block gasket

when replacing electrodes.

B

During every service, replace the gasket at

the gas connection flange of the gas valve.

B

Generally, replace damaged gaskets or

ones that appear aged.

We recommend the replacement of the

electrode block as part of the annual service.