4

Transporting the boiler

Logano plus GB402 - Subject to technical modifications!

15

4.1.1

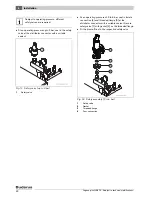

Lifting the boiler off the pallet

B

Remove 4 safety screws [1].

Fig. 5

Separating the boiler from the pallet

1

Safety screws

2

Fixing bar

4.2

Transporting the boiler on rollers

If the path to the boiler room is level, the boiler can also be

rolled. For this, use at least 5 pipes of approx. 900 mm

length (R 1¼ " diameter) as rolling supports.

B

Position the pipes approx. 400 mm apart on the floor.

B

Lift the boiler onto the pipe sections and carefully

transport it to the installation room.

Fig. 6

Transporting the boiler on rollers

(measurements in mm)

NOTICE:

Boiler damage through impact.

The boiler is at risk of tipping over if it is

pushed off the side of the pallet.

B

Push the boiler off the pallet towards the

burner or flue gas side. When pushing the

boiler from the flue gas side, remove fixing

bar [2].

B

Prevent the boiler from coming down hard.

Commercially available transport rollers can

be used.

B

Ensure even load distribution on the load-

bearing parts to prevent distortion of the

bottom plate.

Protect boiler from contamination if the boiler

is not to be taken into use immediately.

Dispose of packaging in an environmentally

responsible manner.