- 193 -

ENG

HEAD FITTING

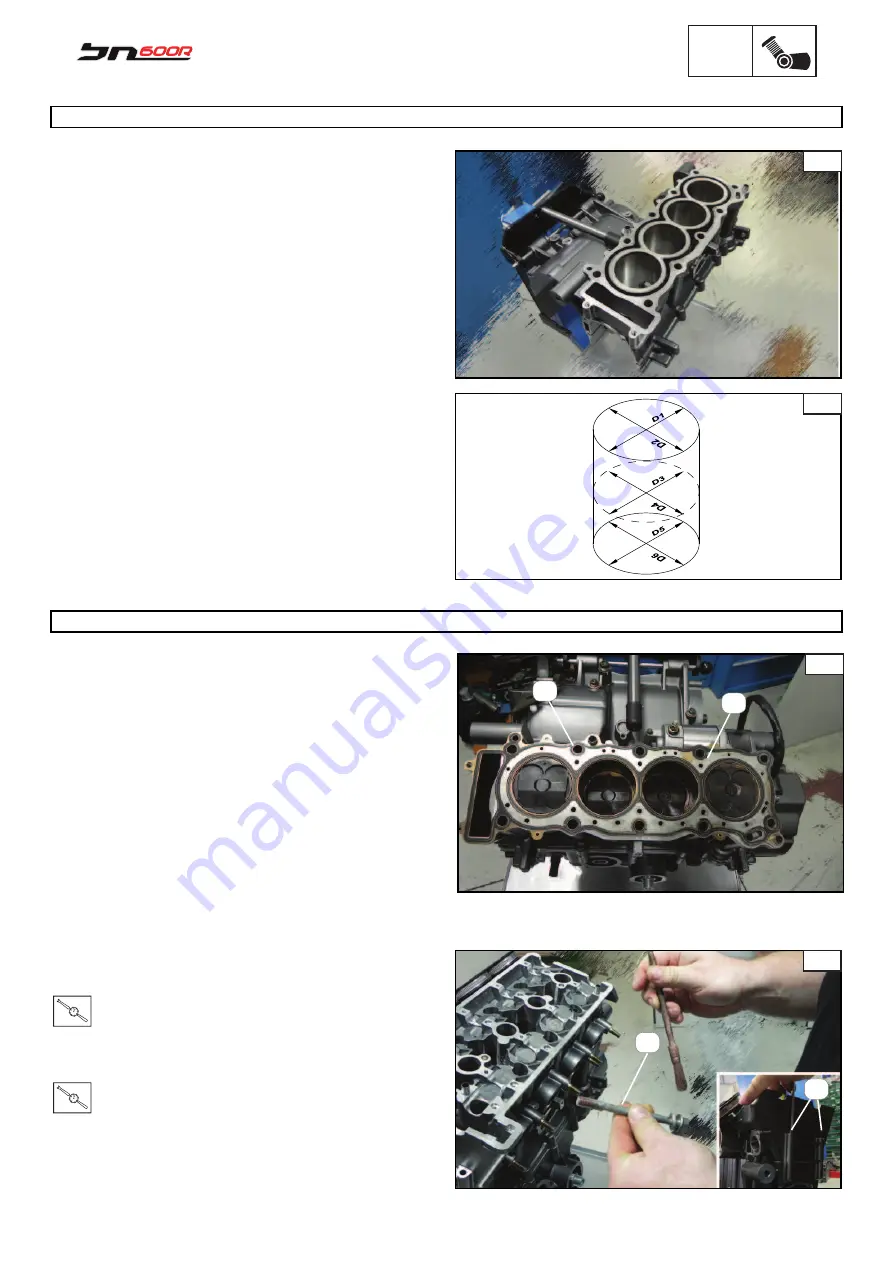

D

Before assembling the head, replace the seal (12).

Make sure that the centering pin (11) is in position Fig. C

To assemble the head, fi rst tighten the 10 fastening screws (X)

Fig. D and then the two allen screws (6).

NOTE

During assembly of the head. lubricate the head screws with

copper grease.

Tighten the screws (X) to the following torque:

T.R.

Torque 55 N*m

Tighten the screws (6) to the following torque:

T.R.

Torque 12 N*m

X

6

HEAD TIMING GEAR

C

12

11

CYLINDER CHECK

The following procedure applies the whole cylinder group.

Check:

•

the walls of the cylinder Fig.A

If there are any vertical lines, replace the cylinder and the piston

all together and the relevant clips.

•

The cooling cavity of the cylinder, in case of build up, remo-

ve scale deposits.

Measure:

•

Cylinder stroke Fig. B

Take different measurements at a distance f 10-43-90 mm from

the head coupling.

The highest value is considered when calculating wear limits.

CYLINDER Bore (C)= 65x45.2

C=Max D1 or D2 65

A

B

- 0.002

- 0.003

mm

Summary of Contents for 2014 BN600

Page 1: ...SERVICE STATION MANUAL code Pure Passion since 1911 ...

Page 6: ...GEN INFO 5 GEN INFO General Information CHAPTER 1 ...

Page 19: ...SPEC 18 SPEC Specifications CHAPTER 2 ...

Page 37: ...CHK ADJ 36 CHK ADJ Inspections and Periodic Adjustments CHAPTER 3 ...

Page 40: ...CHK ADJ 39 NOTES ...

Page 80: ...CHAS 79 Frame CHAPTER 4 CHAS ...

Page 175: ... 174 ENG ENG Engine CHAPTER 5 ...