Installation & Start-Up

|

3-5

Analyzer Installation

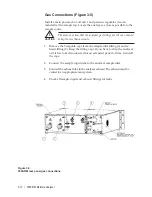

Consult plant safety personnel for appropriate exhaust venting guide-

lines for specific sample gas type.

User-Supplied Items

Interconnect Wiring

The user must supply all wiring for serial communication, analog

output, and alarm relays. Recommended wire is 22 gauge, twisted/

shielded pair.

External Sample Tubing

Sample input tubing length should be as short as possible.

- For optimum performance, sample tubing should be thermally con-

trolled to maintain a constant sample input temperature. Optimal

results are obtained with the sample line maintained at 60 °C.

- Recommended sample gas input tubing is 1/8 inch OD, electro

polished 316L VAR stainless steel (AMETEK #257707000 or equiva-

lent).

Exhaust pressure must be 0 – 15 PSIG.

!

CAUTION

Summary of Contents for 3050-RM

Page 11: ... xi ...

Page 20: ...1 8 3050 RM Moisture Analyzer This page intentionally left blank ...

Page 24: ...2 4 3050 RM Moisture Analyzer This page intentionally left blank ...

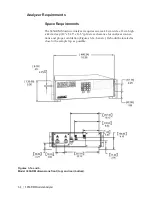

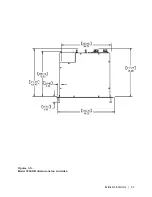

Page 27: ...Installation Start Up 3 3 Figures 3 1c Model 3050 RM dimensions top and sides ...

Page 44: ...4 2 3050 RM Moisture Analyzer Figure 4 2 Menu map for 3050 RM Moisture Analyzer ...

Page 63: ...Serial Communications 5 7 Figure 5 6 Defined Failure Codes ...

Page 64: ...5 8 3050 RM Moisture Analyzer Figure 5 7a Variable Table ...

Page 65: ...Serial Communications 5 9 Figure 5 7b Variable Table ...

Page 66: ...5 10 3050 RM Moisture Analyzer This page intentionally left blank ...

Page 78: ...7 2 3050 RM Moisture Analyzer This page intentionally left blank ...

Page 91: ...Service Parts 8 13 Figure 8 9 Electronic Module ...

Page 98: ...PPmV Centigrade Fahrenheit lbs mnscf mg Nm3 ppmW ...