1-6 | 3050-RM Moisture Analyzer

NOTE

NOTE

Verifying the Analyzer

The verify process is used to correct for aging characteristics of the sen-

sor assembly and potential fouling of the sensor by components of the

sample stream. By measuring the response of the sensor to an internally

generated “moisture standard,” any variations in sensor performance can

be effectively compensated for. During the verification operation, a new

span factor is calculated for the sensor, and this value is then applied for

all subsequent readings.

AMETEK recommends performing a verification cycle monthly.

However, no verification cycle should be performed during the startup

of the analyzer. It is recommended to allow the analyzer and internal

moisture generator to stabilize for a period of 24 hours after applying

power, before running a verification cycle.

Changing Gases

If you are selecting a different gas, the analyzer will need time to purge

the intenal volumes and to stabilize flow. To prevent false alarms from

occurring during this time, the display on the analyzer will read New Gas

and the analyzer will automatically purge itself. This purge period lasts

for forty minutes. During this period, the Data Valid contact is opened

and the flow alarms are suppressed.

You can abort this purge process by pressing the

Verify key, scrolling

to

Abort and then pressing Enter. If the process is aborted, normal

sampling will resume after the completion of the current measure-

ment cycle.

Dew/Frost Point Measurements

Dew point values are calculated from the moisture concentration mea-

surements (PPMV) and the sample or process pressure. For temperatures

below 0 °C, the 3050-RM uses equations to determine the water vapor

pressure over ice, rather than over super-cooled water. Thus, the 3050-RM

reports a frost-point temperature consistent with the physical form of the

condensed phase in a real process stream.

Water in super-cooled liquid state will only exist as a transient species,

as the first bit of condensate starts to form on a smooth-chilled surface

(i.e., the true method of measuring a dew point).

Summary of Contents for 3050-RM

Page 11: ... xi ...

Page 20: ...1 8 3050 RM Moisture Analyzer This page intentionally left blank ...

Page 24: ...2 4 3050 RM Moisture Analyzer This page intentionally left blank ...

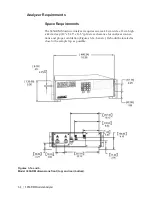

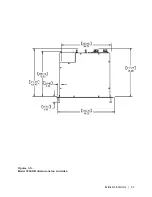

Page 27: ...Installation Start Up 3 3 Figures 3 1c Model 3050 RM dimensions top and sides ...

Page 44: ...4 2 3050 RM Moisture Analyzer Figure 4 2 Menu map for 3050 RM Moisture Analyzer ...

Page 63: ...Serial Communications 5 7 Figure 5 6 Defined Failure Codes ...

Page 64: ...5 8 3050 RM Moisture Analyzer Figure 5 7a Variable Table ...

Page 65: ...Serial Communications 5 9 Figure 5 7b Variable Table ...

Page 66: ...5 10 3050 RM Moisture Analyzer This page intentionally left blank ...

Page 78: ...7 2 3050 RM Moisture Analyzer This page intentionally left blank ...

Page 91: ...Service Parts 8 13 Figure 8 9 Electronic Module ...

Page 98: ...PPmV Centigrade Fahrenheit lbs mnscf mg Nm3 ppmW ...