3-10 | 3050-RM Moisture Analyzer

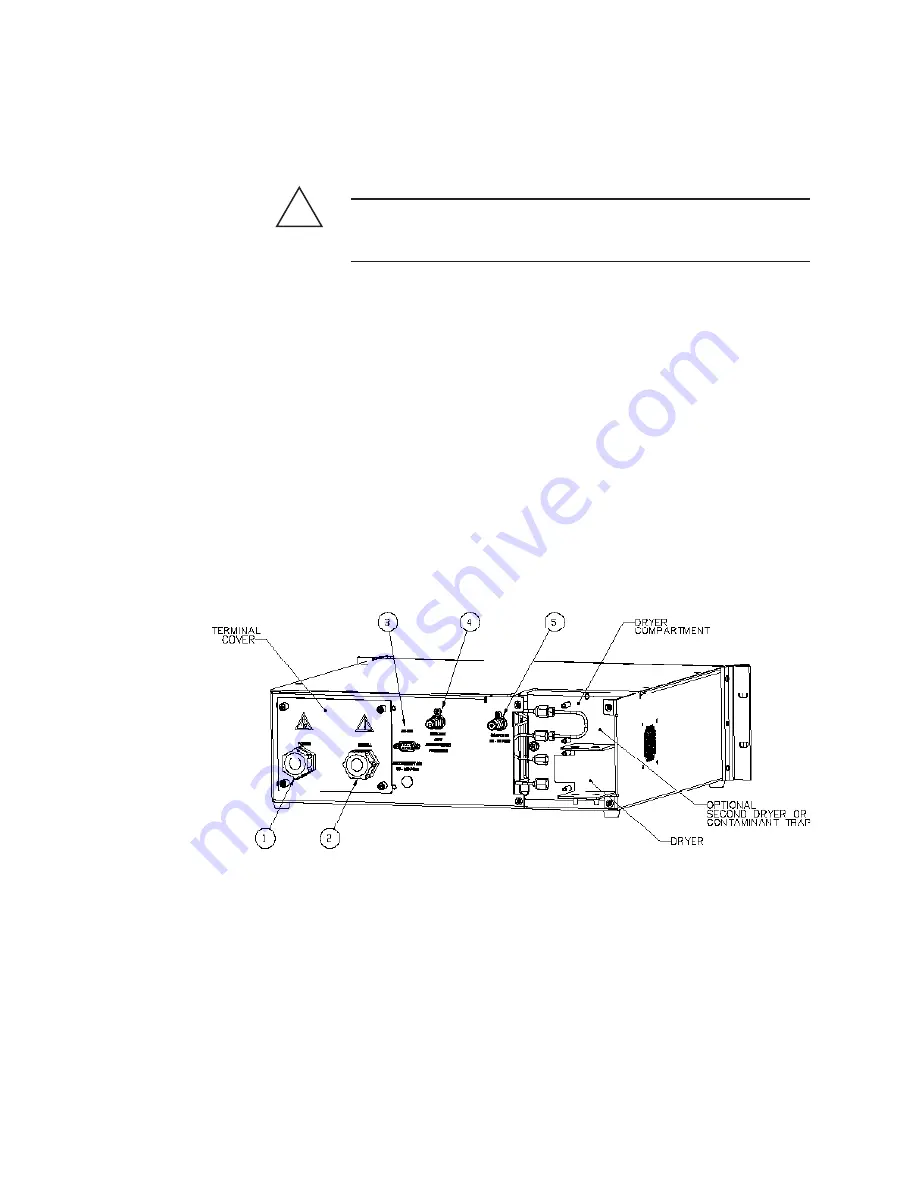

Gas Connections (Figure 3-5)

Install a main process shut-off valve and pressure regulator (recom-

mended) at the sample tap. Locate the analyzer as close as possible to the

sample source.

The amount of time that the analyzer gas fittings are left open should

be kept to less than a minute.

1. Remove the Swagelok caps from the sample inlet fitting (6) and ex-

haust fitting (5). Keep the fitting caps. If you have to ship the analyzer

or if it has to be disconnected for an extended period of time, reinstall

the caps.

2. Connect the sample input tube to the analyzer sample inlet.

3. Connect the exhaust tube to the analyzer exhaust. The exhaust must be

vented to an appropriate vent system.

4. Check all sample input and exhaust fittings for leaks.

!

CAUTION

Figure 3-5.

3050-RM rear panel gas connections.

Summary of Contents for 3050-RM

Page 11: ... xi ...

Page 20: ...1 8 3050 RM Moisture Analyzer This page intentionally left blank ...

Page 24: ...2 4 3050 RM Moisture Analyzer This page intentionally left blank ...

Page 27: ...Installation Start Up 3 3 Figures 3 1c Model 3050 RM dimensions top and sides ...

Page 44: ...4 2 3050 RM Moisture Analyzer Figure 4 2 Menu map for 3050 RM Moisture Analyzer ...

Page 63: ...Serial Communications 5 7 Figure 5 6 Defined Failure Codes ...

Page 64: ...5 8 3050 RM Moisture Analyzer Figure 5 7a Variable Table ...

Page 65: ...Serial Communications 5 9 Figure 5 7b Variable Table ...

Page 66: ...5 10 3050 RM Moisture Analyzer This page intentionally left blank ...

Page 78: ...7 2 3050 RM Moisture Analyzer This page intentionally left blank ...

Page 91: ...Service Parts 8 13 Figure 8 9 Electronic Module ...

Page 98: ...PPmV Centigrade Fahrenheit lbs mnscf mg Nm3 ppmW ...