Settings

P846/EN ST/D

MiCOM P846

(ST) 4-15

ST

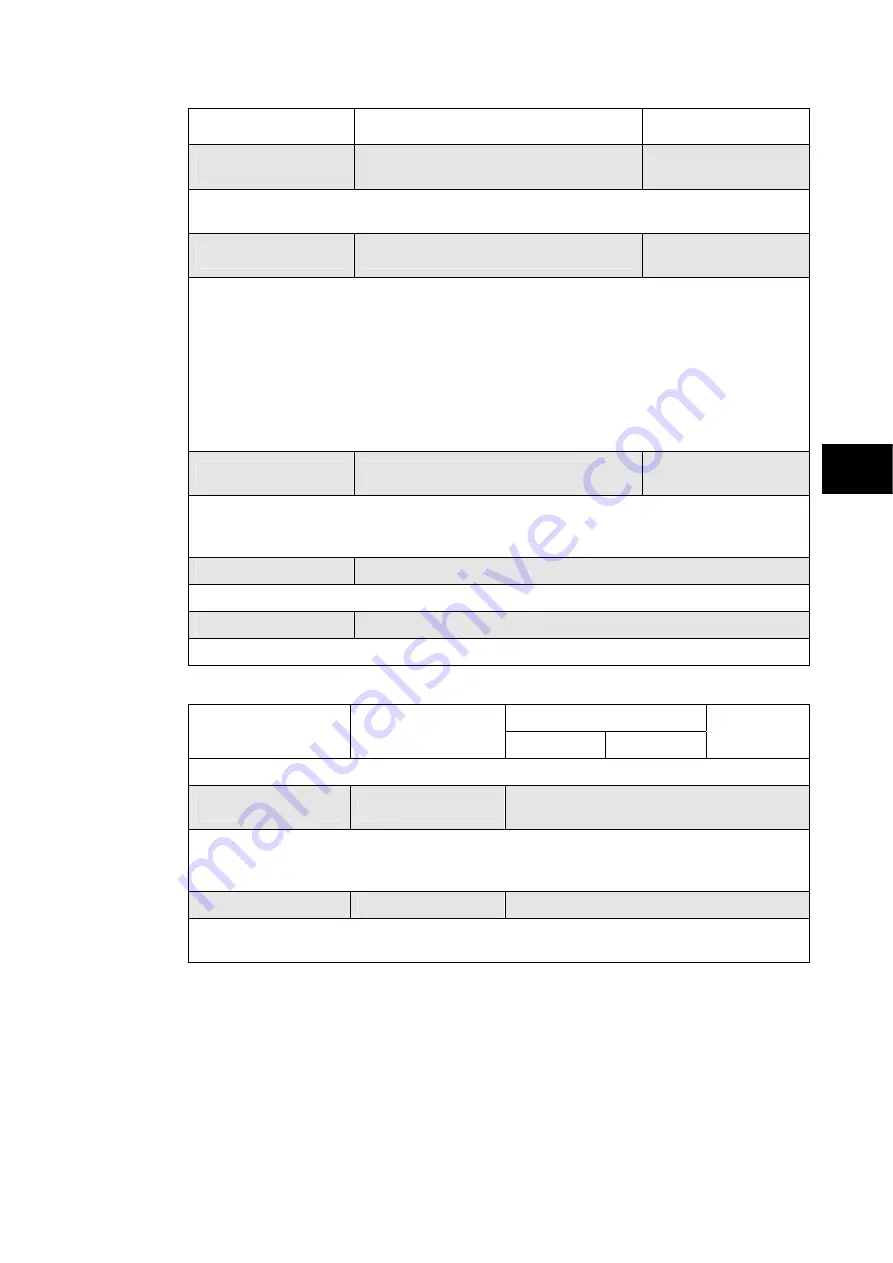

Menu Text

Default Setting

Available Settings

Test Pattern

00000000000000000000000000000000

0 = Not Operated

1 = Operated

This cell is used to select the output relay contacts that will be tested when the ‘Contact

Test’ cell is set to ‘Apply Test’.

Contact Test

No Operation

No Operation, Apply

Test, Remove Test

When the ‘Apply Test’ command in this cell is issued the contacts set for operation (set to

‘1’) in the ‘Test Pattern’ cell change state. After the test has been applied the command

text on the LCD will change to ‘No Operation’ and the contacts will remain in the Test State

until reset issuing the ‘Remove Test’ command. The command text on the LCD will again

revert to ‘No Operation’ after the ‘Remove Test’ command has been issued.

Note: When the ‘Test Mode’ cell is set to ‘Enabled’ the ‘Relay O/P Status’ cell does not

show the current status of the output relays and hence can not be used to confirm

operation of the output relays. Therefore it will be necessary to monitor the state

of each contact in turn.

Test LEDs

No Operation

No Operation

Apply Test

When the ‘Apply Test’ command in this cell is issued the eighteen user-programmable

LEDs will illuminate for approximately 2 seconds before they extinguish and the command

text on the LCD reverts to ‘No Operation’.

DDB 31 - 0

00000000000000000000001000000000

Displays the status of DDB signals 0-31.

DDB 1022 - 992

00000000000000000000000000000000

Displays the status of DDB signals 1022 – 992.

1.3.8

Opto configuration

Setting Range

Menu Text

Default Setting

Min. Max.

Step Size

OPTO CONFIG.

Global Nominal V

24 - 27

24 - 27, 30 - 34, 48 - 54, 110 - 125,

220 - 250, Custom

Sets the nominal battery voltage for all opto inputs by selecting one of the five standard

ratings in the Global Nominal V settings. If Custom is selected then each opto input can

individually be set to a nominal voltage value.

Opto Filter Cntl.

1111111111111111

Selects each input with a pre-set filter of ½ cycle that renders the input immune to induced

noise on the wiring.

Summary of Contents for MiCOM P846

Page 2: ......

Page 4: ......

Page 5: ...Safety Section P846 EN SS H11 SS SAFETY SECTION...

Page 6: ...P846 EN SS H11 Safety Section SS...

Page 8: ...P846 EN SS H11 Safety Section SS 2 SS...

Page 16: ...P846 EN IT D Introduction MiCOM P846 IT...

Page 18: ...P846 EN IT D Introduction IT 1 2 MiCOM P846 IT...

Page 26: ...P846 EN TD D Technical Data MiCOM P846 TD...

Page 38: ...P846 EN GS D Getting Started MiCOM P846 GS...

Page 58: ...P846 EN ST D Getting Started MiCOM P846 ST...

Page 60: ...P846 EN ST D Settings ST 4 2 MiCOM P846 ST...

Page 78: ...P846 EN OP D Operation MiCOM P846 OP...

Page 104: ...P846 EN OP D Operation OP 5 26 MiCOM P846 OP...

Page 106: ...P846 EN AP D Application Notes MiCOM P846 AP...

Page 108: ...P846 EN AP D Application Notes AP 6 2 MiCOM P846 AP...

Page 122: ...P846 EN AP D Application Notes AP 6 16 MiCOM P846 AP...

Page 124: ...P846 EN PL D Programmable Logic MiCOM P846 PL...

Page 126: ...P846 EN PL D Programmable Logic PL 7 2 MiCOM P846 PL...

Page 144: ...P846 EN MR D Measurements and Recording MiCOM P846 MR...

Page 146: ...P846 EN MR D Measurements and Recording MR 8 2 MiCOM P846 MR...

Page 160: ...P846 EN FD D Firmware Design MiCOM P846 FD...

Page 182: ...P846 EN CM D Commissioning MiCOM P846 CM...

Page 228: ...P846 EN CM D Commissioning CM 10 46 MiCOM P846 CM...

Page 230: ...P846 EN MT D Maintenance MiCOM P846 MT...

Page 232: ...P846 EN MT D Maintenance MT 11 2 MiCOM P846 MT...

Page 238: ...P846 EN TS D Troubleshooting MiCOM P846 TS...

Page 240: ...P846 EN TS D Troubleshooting TS 12 2 MiCOM P846 TS...

Page 252: ...P846 EN SC D SCADA Communications MiCOM P846 SC...

Page 272: ...P846 EN SG D Symbols and Glossary MiCOM P846 SG...

Page 280: ...P846 EN SG D Symbols and Glossary SG 14 8 MiCOM P846 SG...

Page 282: ...P846 EN IN D Installation MiCOM P846 IN...

Page 284: ...P846 EN IN D Installation IN 15 2 MiCOM P846 IN...

Page 296: ...P846 EN IN D Installation IN 15 14 MiCOM P846 IN...

Page 297: ......