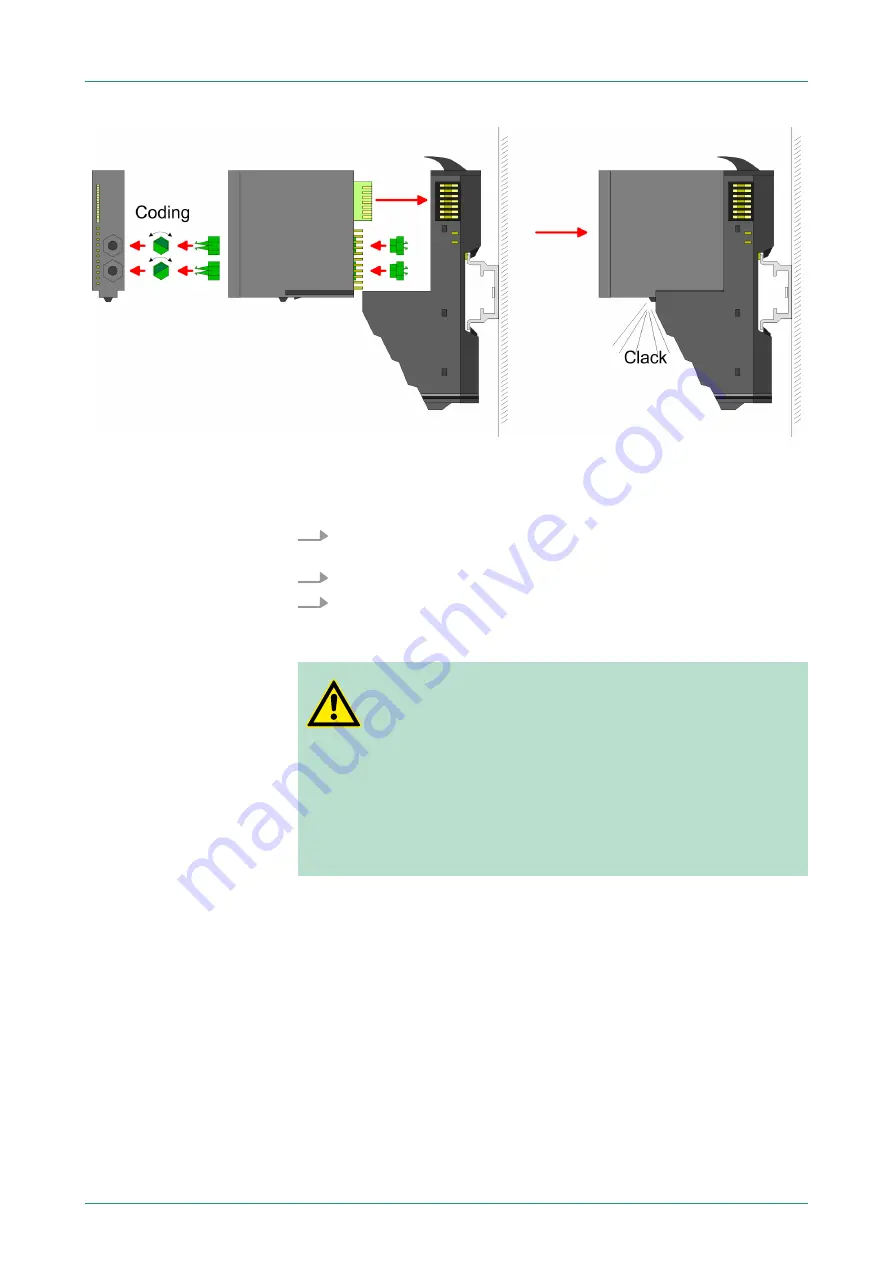

Each electronic module has on its back 2 coding sockets for coding

jacks. Due to the characteristics, with the coding jack 6 different posi-

tions can be plugged, each. Thus there are 36 possible combinations

for coding with the use of both coding sockets.

1.

Plug, according to your coding, 2 coding jacks in the coding

sockets of your electronic module until they lock.

2.

Now plug the according coding plugs into the coding jacks.

3.

To fix the coding put both the electronic and terminal module

together until they lock.

CAUTION!

Please consider that when replacing an already coded

electronic module, this is always be replaced by an elec-

tronic module with the same coding.

Even with an existing coding on the terminal module, you

can plug an electronic module without coding. The user is

responsible for the correct usage of the coding pins. VIPA

assumes no liability for incorrectly attached electronic

modules or for damages which arise due to incorrect

coding!

The modules were directly be mounted to the mounting rail and so

connected to the backplane bus and the power supply for the elec-

tronic and power section. Up to 64 modules may be mounted. Please

consider here that the sum current of the electronic power supply

does not exceed the maximum value of 3A. By means of the power

module 007-1AB10 the current of the electronic power supply may be

expanded with 2A.

Chapter 2.6 ‘Wiring’ on page 23

Mounting Proceeding

VIPA System SLIO FM 050

Basics and Assembly

Installation

HB300 | FM | 050-1BA00 | GB | 15-11

16