ENGINE

6-38

3TNV88F Service Manual

Crankshaft and Camshaft Components

2. Measure bearing oil clearance prior to removing

the pistons and connecting rods to determine

extent of wear. Record the measurements.

NOTICE

Mark the connecting rod caps and connecting

rods so the caps and connecting rods stay

together.

1- Remove the bearing cap. Do not remove the

bearing inserts at this time.

2- Wipe oil from the bearing insert and

crankshaft journal surfaces.

3- Place a piece of PLASTIGAGE

®

along the full width of the

bearing insert.

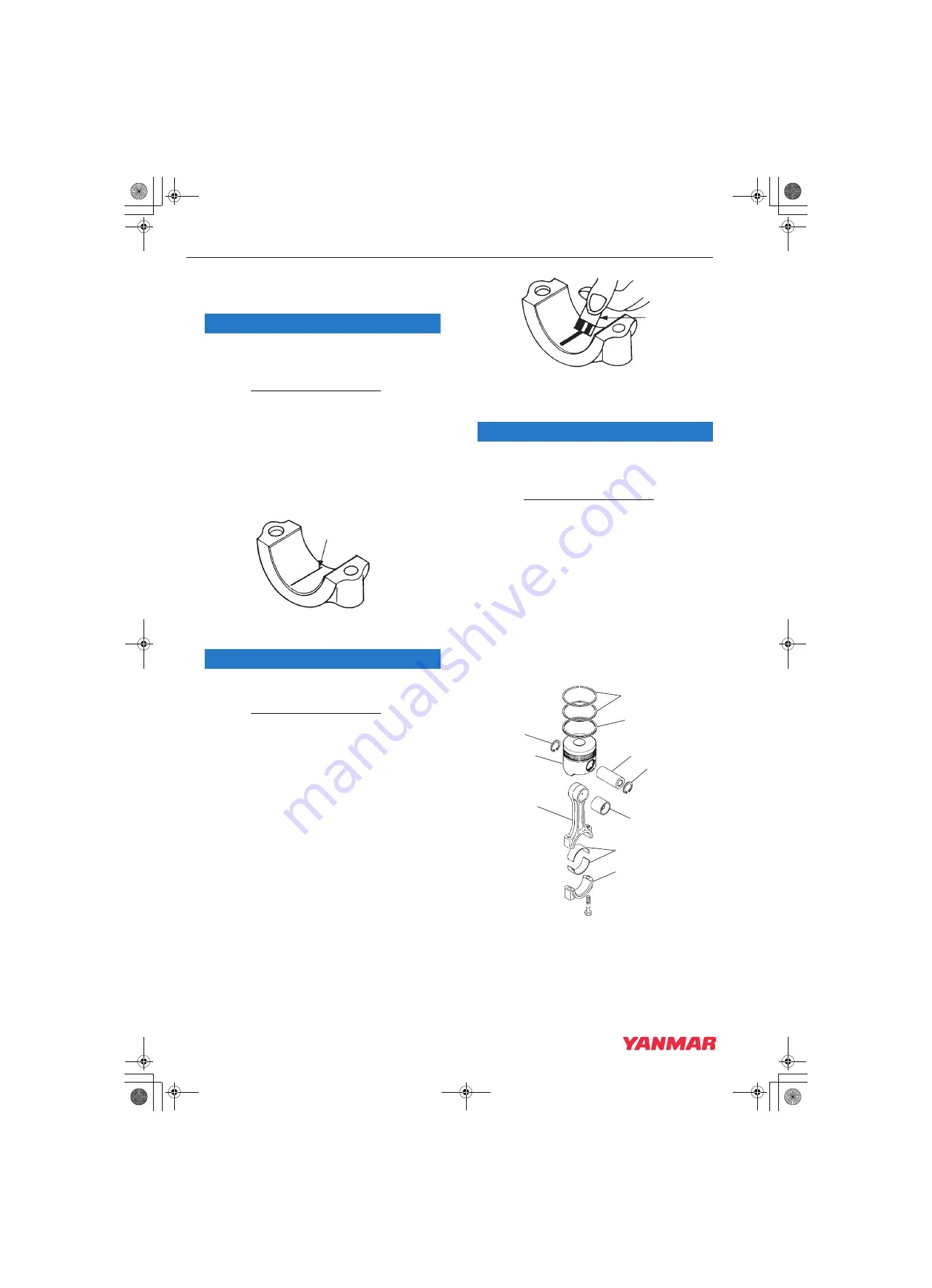

Figure 6-53

NOTICE

Do not rotate the crankshaft when using

PLASTIGAGE. A false reading may result.

4- Reinstall bearing cap and tighten to

specification.

5- Remove bearing cap.

6- Compare the width of the flattened

PLASTIGAGE to the graduation marks on

the package

(Figure 6-54, (1))

. The mark

that most closely matches the width of the

flattened PLASTIGAGE will indicate the

bearing oil clearance.

Figure 6-54

7- Repeat with remaining connecting rods.

NOTICE

Do not allow the connecting rod to contact the

crankshaft journal during piston removal.

Damage to the bearing journal may result.

3. Use a wooden dowel against the connecting

rod and tap the piston/connecting rod assembly

out of the cylinder.

4. Mark the cylinder number on the piston and

connecting rod.

5. Remove the bearing inserts

.

6. Remove the compression rings

(Figure 6-55, (3))

from the piston using a piston

ring expander.

7. Remove the oil ring

(Figure 6-55, (4))

from the

piston using a piston ring expander.

Figure 6-55

K0001898

1

K0001899

1

3

4

5

9

6

8

7

5

2

1

K0001960

3TNV88F_SVM_A4.book 38 ページ 2012年7月26日 木曜日 午後6時4分