FUEL SYSTEM

7-28

3TNV88F Service Manual

Fuel Injectors

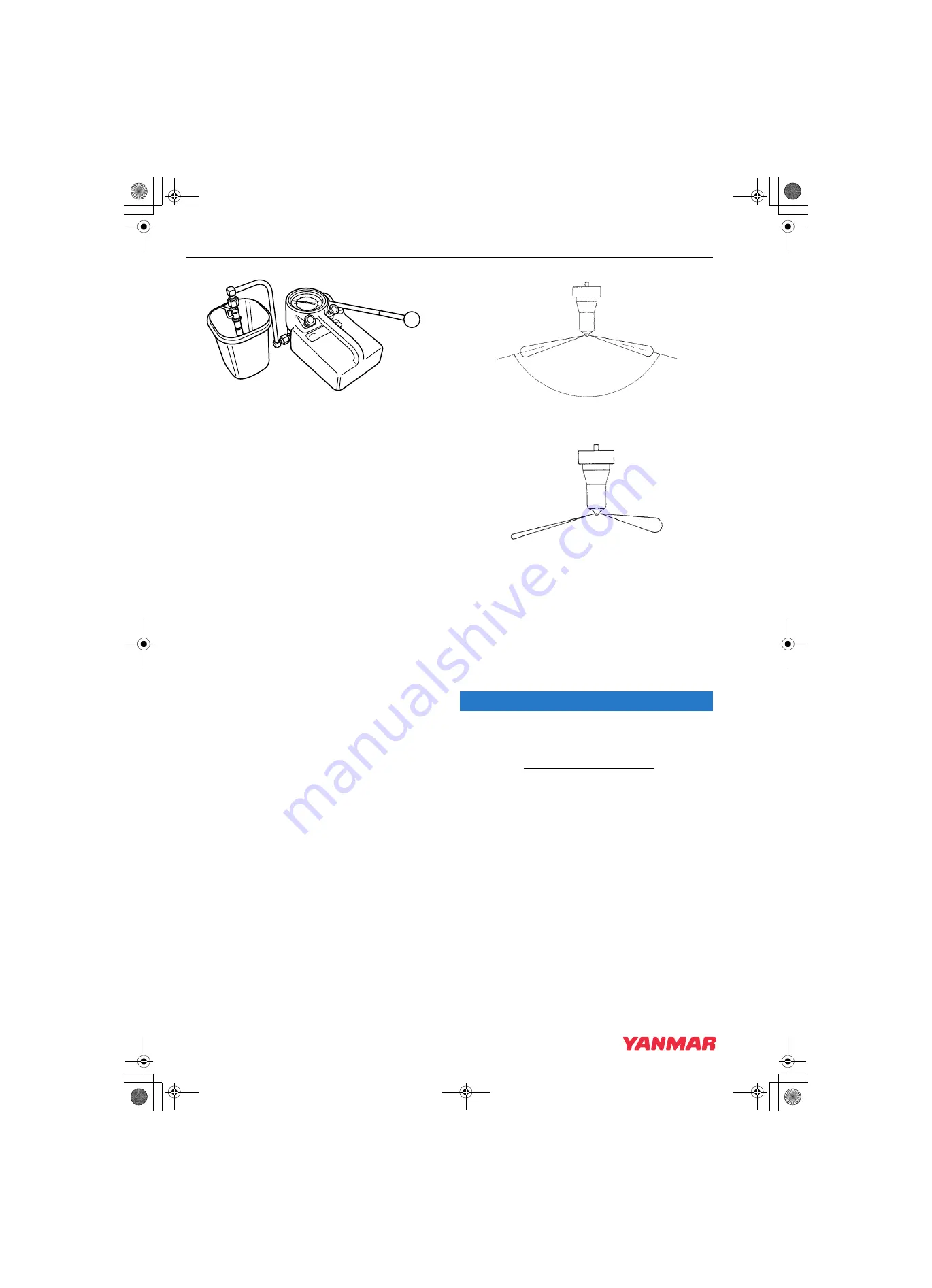

Figure 7-46

4. Pump the operating lever of the tester slowly,

observing the pressure reading at the point

where the fuel injector begins spraying fuel

.

for injector ID location.

See Test and Adjustment Specifications on

page 7-6 for correct pressure readings.

Note: The opening pressure of a new fuel

injector will be approximately 0.5 MPa (5

kgf/cm

2

, 72.5 PSI) higher than one that

has been operated for five hours or

longer.

5. Pump the operating lever slowly to hold the

pressure steady at a point just below the

opening pressure and hold it for 5 seconds.

Observe the injector to see that it is sealing

properly and is not “dripping”. If fuel leaks from

the return line fitting, check that the nozzle case

nut is tight. Service or replace the injector if fuel

continues to leak from either the return line

fitting or nozzle.

6. Pump the operating lever more rapidly to

repeatedly “pop” the injector and observe the

spray pattern. The pattern should be a very fine

uniform spray

If a dripping or an

uneven pattern is seen

, service

or replace the injector.

Figure 7-47

Figure 7-48

If the fuel injector fails any of these tests, it should

be serviced or replaced as necessary. If the

pressure is outside specified limits, adjust the

pressure.

See Adjusting Fuel Injector Pressure

Disassembly and Inspection of Fuel

Injectors

NOTICE

Never use a steel wire brush to clean fuel injectors.

Damage to the nozzle and other components is

likely to result.

1. Clean carbon from used injectors using clean

diesel fuel. Hardened deposits or varnish can

be cleaned using a brass wire brush.

-GA

GE-

P-

ON

OFF

OFF

K0000581

K0001336A

K0001337A

3TNV88F_SVM_A4.book 28 ページ 2012年7月26日 木曜日 午後6時4分