ENGINE

3TNV88F Service Manual

6-51

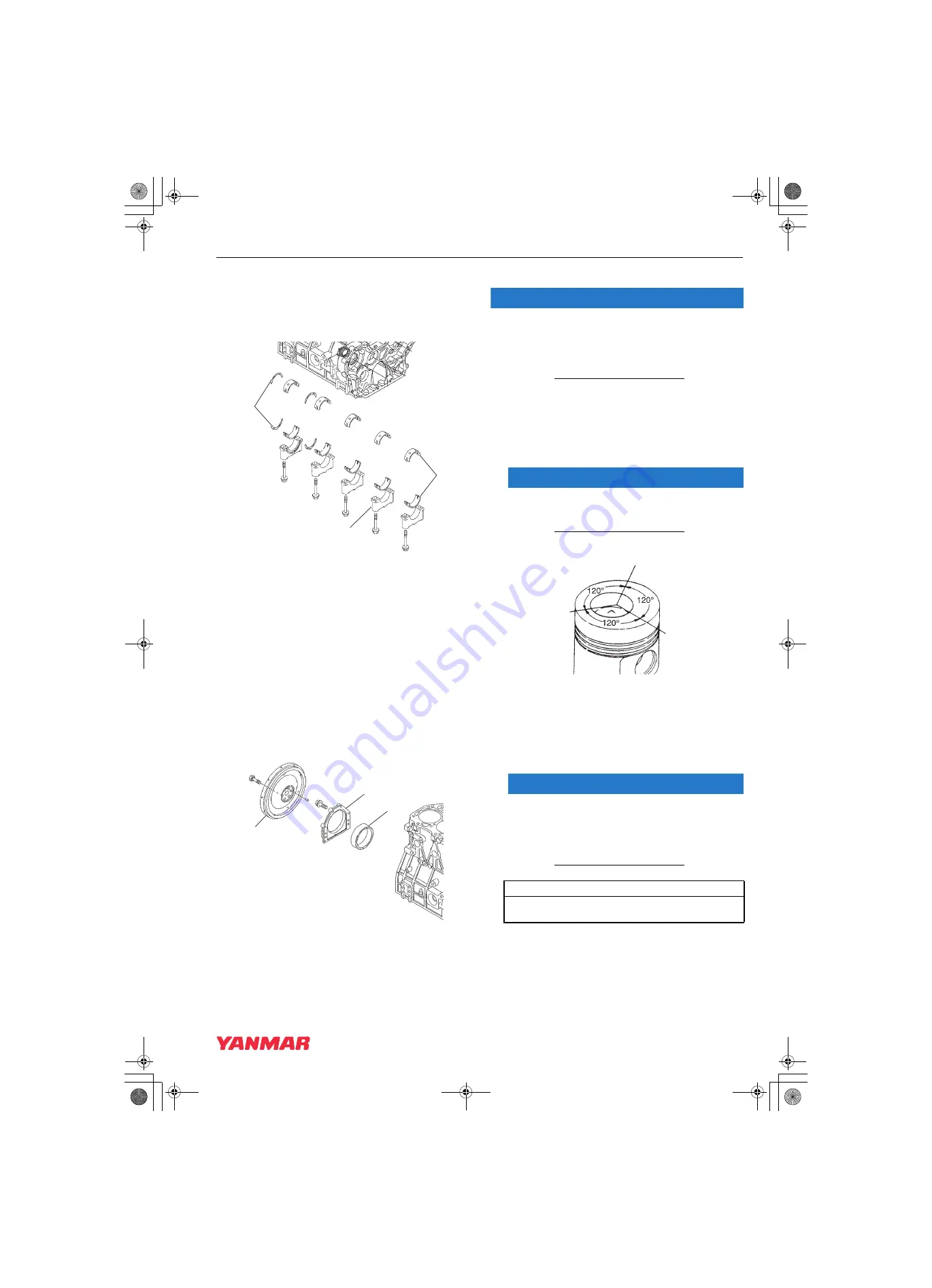

Crankshaft and Camshaft Components

5. Apply a light coat of clean engine oil to the

bearing cap bolts and tighten the bolts to the

specified torque in two stages (1/2 then full

torque).

page 6-10 for specifications.

Figure 6-89

6. Rotate the crankshaft to assure it turns freely.

7. Apply ThreeBond Liquid Gasket No. 1207F,

YANMAR Part No. 977770-1207F to the

mounting flange of the seal housing

.

8. Align the seal housing

with the two dowel pins.

9. Reinstall seal housing and seal assembly.

10. Reinstall the flywheel

(Figure 6-90, (1))

and

tighten the bolts to the specified torque.

Special Torque Chart on page 6-10 for

specifications.

Figure 6-90

■

Installation of pistons

NOTICE

Do not allow the connecting rod to contact the

crankshaft journal during piston installation.

Damage to the crankshaft bearing journal may

result.

1. Lubricate the piston, piston rings, and cylinder

with clean engine oil or assembly lubricant.

2. Rotate the crankshaft so the crankpin for the

piston being installed is near bottom dead

center.

NOTICE

Ensure the piston ring gaps are located correctly

1 – Top compression ring end gap

2 – Second compression ring end gap

3 – Oil ring end gap

Figure 6-91

3. Using a piston ring compressor, compress the

piston rings.

NOTICE

The piston and connecting rod must be installed

in the correct orientation. The orientation of the

piston to the cylinder is different depending on

engine model.

2

K0001752A

1

3

2

K0001707A

1

3

Piston orientation to cylinder - by model

Orient the piston identification mark stamped on top of the

piston on the fuel injection pump side of the engine

3

1

2

3TNV88F_SVM_A4.book 51 ページ 2012年7月26日 木曜日 午後6時4分