ENGINE

6-44

3TNV88F Service Manual

Crankshaft and Camshaft Components

■

Inspection of tappets

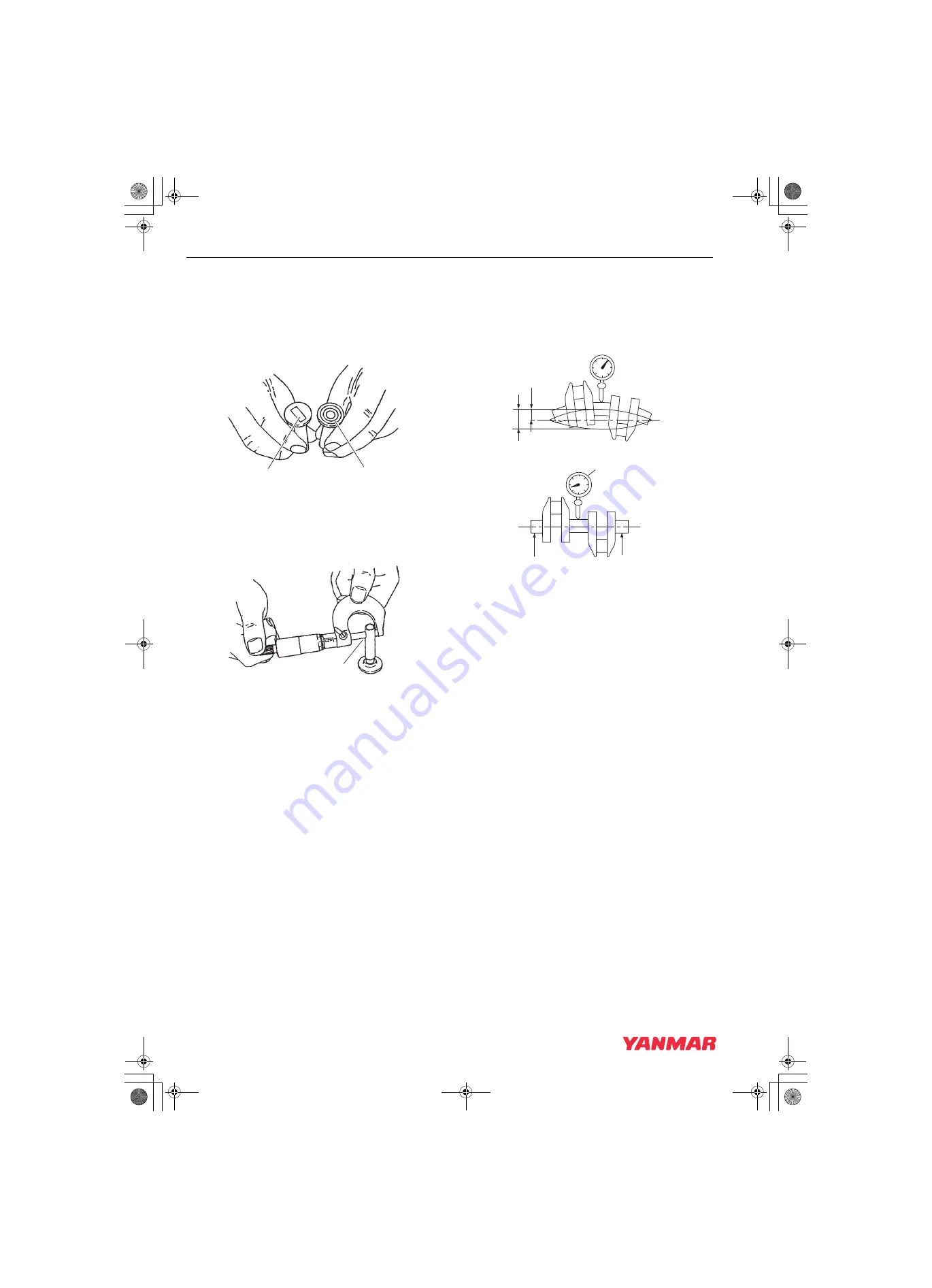

1. Inspect the tappet contact surfaces for

abnormal wear

(Figure 6-72, (1))

. Normal wear

will be even as shown in

Slight surface defects can be corrected using

an oilstone.

Figure 6-72

2. Measure the outside diameter of the tappet

.

page 6-9 for the service limit.

Figure 6-73

3. Measure the tappet bores in the cylinder block.

See Tappet on page 6-9 for the service limit.

■

Inspection of crankshaft

1. Place the crankshaft end journals

(Figure 6-74, (4))

on V-blocks.

on a

center main bearing surface.

Figure 6-74

3. Rotate the crankshaft and observe runout.

Crankshaft on page 6-7 for specifications.

4. Use the color check method or Magnaflux

®

to

inspect the crankshaft for cracks. Replace the

crankshaft if evidence of fractures are found.

5. Measure the outside diameter of each crankpin

(Figure 6-75, (2))

and main bearing journal

(Figure 6-75, (1))

for specifications.

Take measurements at

several places around each bearing surface. If

not within specification, grind the journals and

install undersize bearings, or replace the

crankshaft.

K0001725

1

2

1

K0001726A

K0000232A

2

3

4

4

1

3TNV88F_SVM_A4.book 44 ページ 2012年7月26日 木曜日 午後6時4分