ENGINE

6-36

3TNV88F Service Manual

Crankshaft and Camshaft Components

■

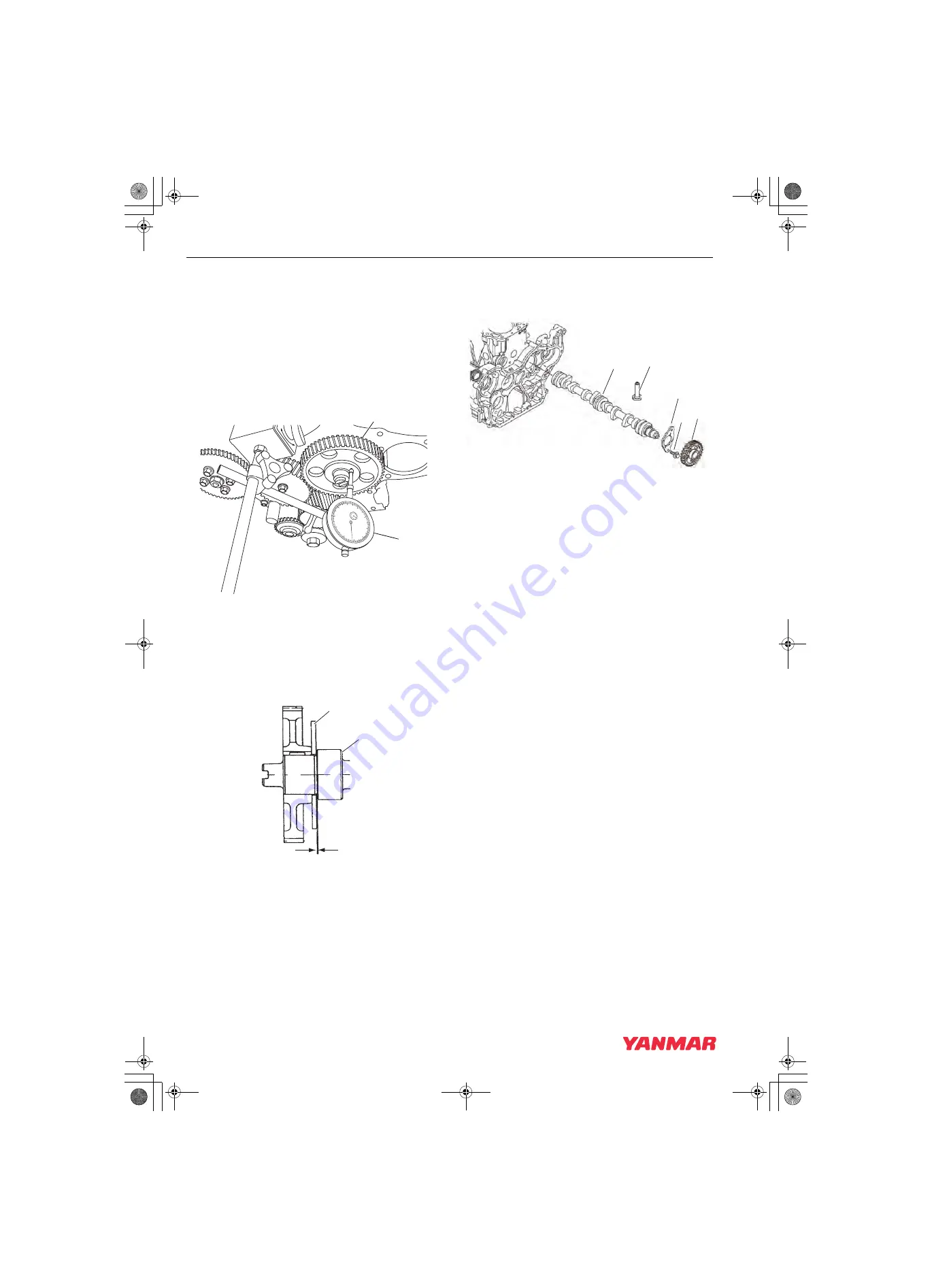

Removal of camshaft

1. Before removing the camshaft, check the

camshaft end play.

•

Method A:

Install a dial indicator

(Figure 6-48, (1))

on the cylinder block. Move

back and forth

to measure the end play. Record the

measurement.

the service limit.

Figure 6-48

•

Method B:

Use a feeler gauge to measure the

clearance between the thrust plate

(Figure 6-49, (1))

and front camshaft bearing

(Figure 6-49, (2))

page 6-7 for the service limit.

Figure 6-49

2. Remove the two bolts

retaining the camshaft thrust plate

(Figure 6-50, (1))

.

Figure 6-50

3. Rotate the engine in the engine stand so that

gravity causes the tappets

to

drop away from the camshaft lobes.

Note: Rotate the camshaft at least two turns to

“bump” any sticking tappets away from

the camshaft.

4. Slowly pull the camshaft

(Figure 6-50, (2))

assembly

out of the engine being careful not to

damage the front camshaft bushing.

Note:

•

If the engine is not installed on an engine repair

fixture, stand the engine upright on the flywheel

end mounting flange. Rotate the camshaft at

least two turns to bump the tappets out of the

way to prevent the tappets from interfering with

the removal of the camshaft.

•

The tappets are “mushroom” shaped and must

be removed from inside the engine crankcase.

5. Remove the tappets. Mark the tappets so they

can be reinstalled in the same location.

6. Remove the camshaft drive gear

(Figure 6-50, (4))

only if the gear or camshaft

require replacement. Use a knife-edge puller

and a press to remove the gear. The gear is a

shrink-fit and will need to be heated to 356 -

392 °F (180 - 200 °C) to remove.

0

10

20

30

40

50

60

70

80

90

K0002085A

1

2

1

2

K0001710B

K0001966

4

1

3

2

5

3TNV88F_SVM_A4.book 36 ページ 2012年7月26日 木曜日 午後6時4分