ENGINE

6-42

3TNV88F Service Manual

Crankshaft and Camshaft Components

1. Clean piston ring grooves using a piston ring

groove cleaning tool. Follow manufacturer’s

instructions for correct operation.

2. Wash the pistons in an appropriate solvent

using a soft brush.

3. Visually inspect each piston for cracks. Pay

particular attention to the ring lands between

the piston ring grooves.

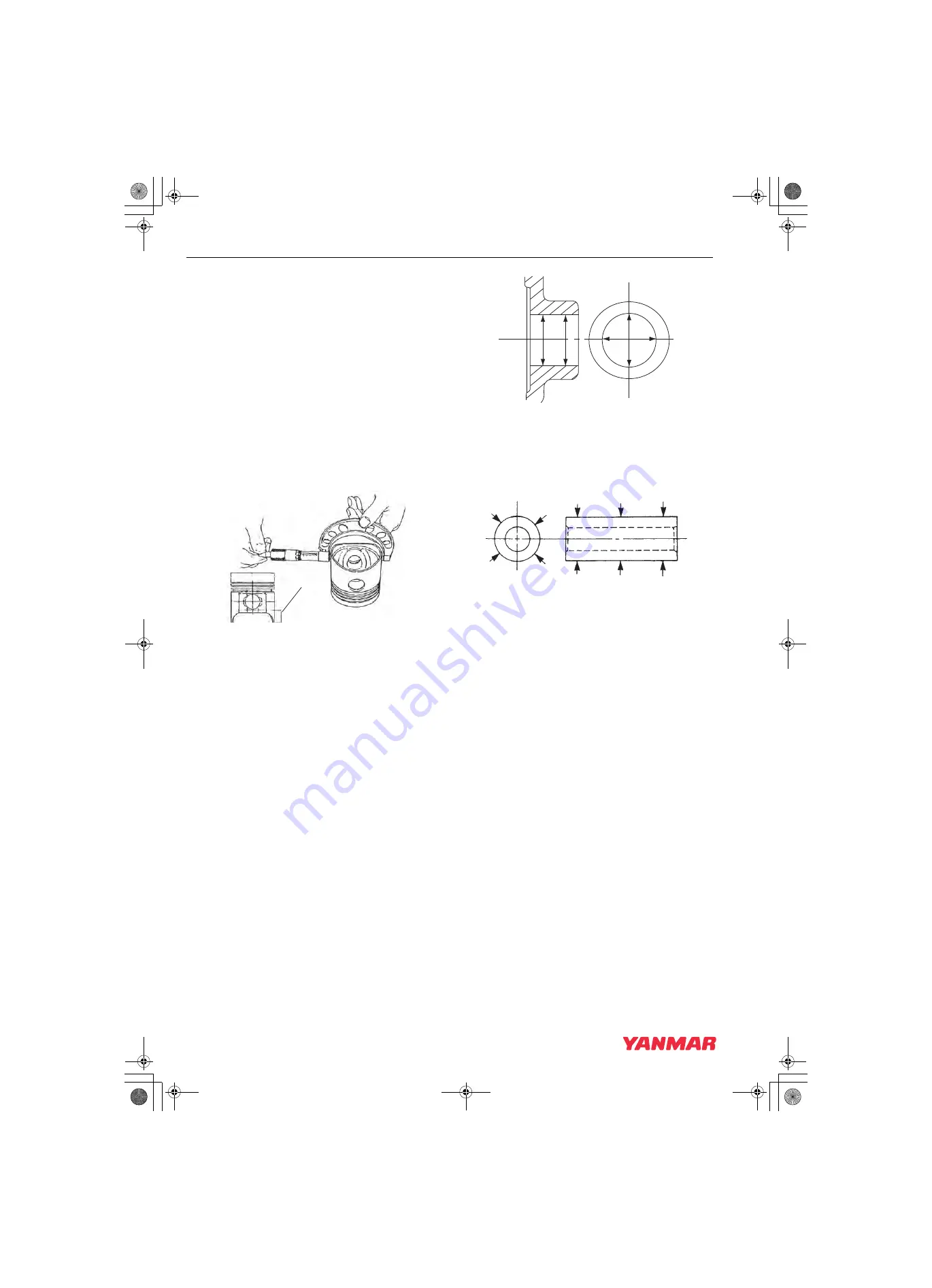

4. Measure the diameter of the piston skirt at 90°

to the wrist pin bore as shown

Measurements must be taken at a specified

distance

from the bottom of

the piston, based on engine model. Record the

measurements.

specifications.

Figure 6-66

5. Subtract the piston measurement from the

greatest measurement acquired during cylinder

inspection

(see Inspection of cylinder block on

to obtain piston-to-cylinder

clearance. Record the measurements.

Piston on page 6-7 for specifications.

6. Measure the diameter of the wrist pin bore on

Piston on page 6-7 for specifications.

Record

the measurements.

Figure 6-67

7. Measure the outside diameter of the wrist pin in

three places and at 90°

Piston on page 6-7 for specifications.

Record

the measurements.

Figure 6-68

8. Using a micrometer, measure the thickness of

specifications.

Record the measurements.

Note:

• On an engine with low hours, the pistons,

piston rings and cylinders may be reused if they

are found to be within specifications.

• On an engine with high hours, the pistons rings

should be replaced and the cylinder honed

(see Honing and Boring on page 6-46) or

replaced. The piston should be replaced as

necessary.

9. Place each compression piston ring in the

groove as shown

. Use a feeler

gauge to measure the clearance between the

piston ring and the piston ring land. Record the

measurements.

for specifications.

Replace the piston if not

within specification.

K0000235

1

K0000237

K0001889

3TNV88F_SVM_A4.book 42 ページ 2012年7月26日 木曜日 午後6時4分