ENGINE

6-50

3TNV88F Service Manual

Crankshaft and Camshaft Components

6. Reinstall the oil ring expander

. Reinstall the oil ring

with the end gap at 180° from

the expander end gap

.

7. Reinstall the second compression ring

This ring is identified by its

dark color and tapered face profile

.

8. Reinstall the top compression ring

. This ring is identified by its

silver color and barrel-shaped face profile.

NOTICE

The oil ring expander

(Figure 6-87, (4))

end gap

must be located 180° from the oil ring

end gap.

Figure 6-87

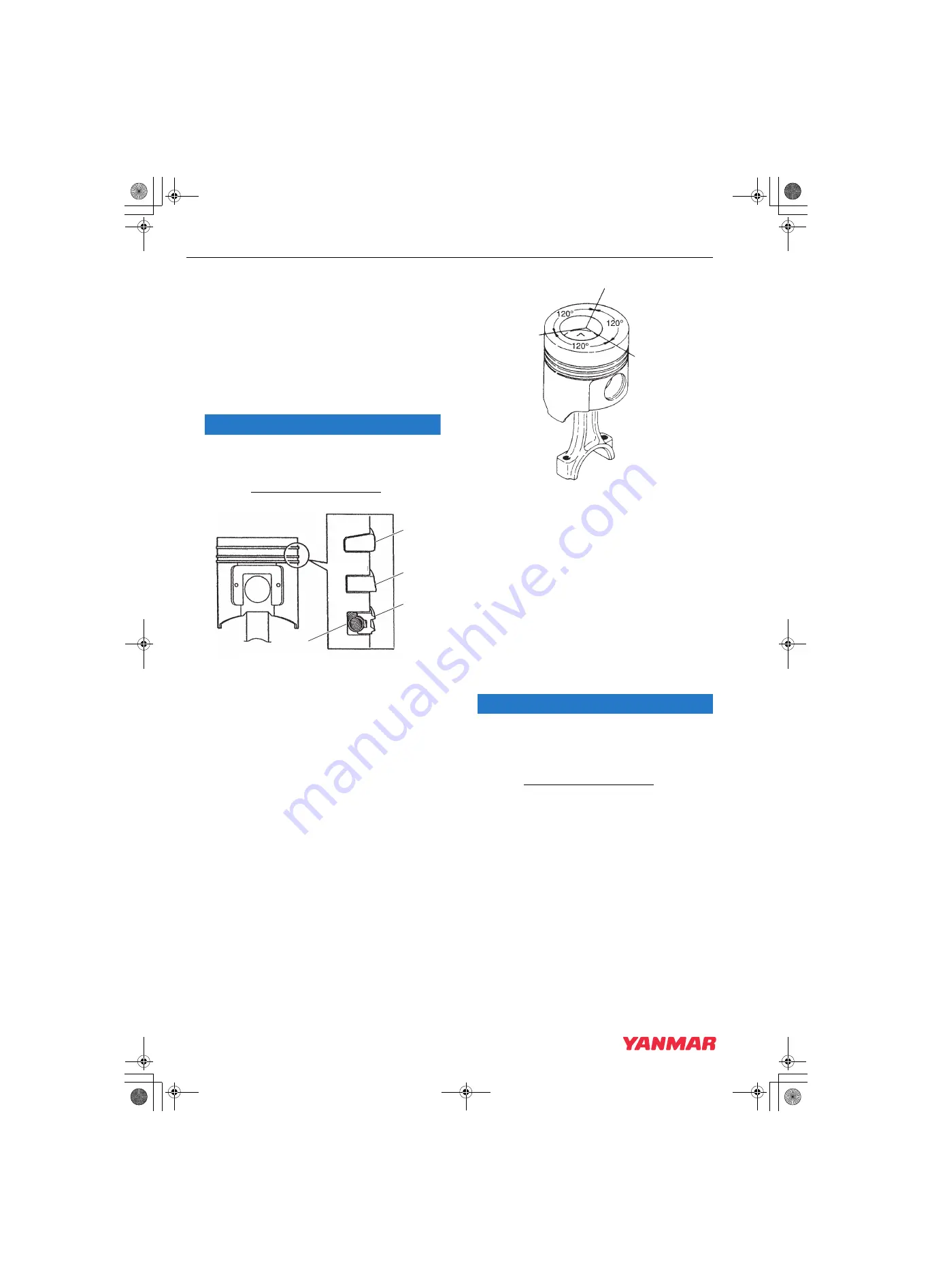

9. Stagger the piston ring end gaps at 120°

intervals

. Do not

position the top piston ring end gap in line with

the wrist pin.

1 – Top compression ring end gap

2 – Second compression ring end gap

3 – Oil ring end gap

Figure 6-88

■

Installation of crankshaft

1. If removed, reinstall the keys and timing gear on

the crankshaft.

2. Reinstall new bearing inserts

and thrust bearing

(Figure 6-89, (2))

in the

cylinder block and main bearing caps. Apply a

liberal coat of clean engine oil to the bearings

and crankshaft journals.

3. Place the crankshaft into the engine.

NOTICE

The main bearing caps are numbered and have

arrows for proper positioning. The No. 1 cap is at

the flywheel end. The arrows point toward the

flywheel end of the engine.

4. Reinstall the main bearing caps

(Figure 6-89, (3))

.

1

2

3

4

K0001722B

3

1

2

K0001968

3TNV88F_SVM_A4.book 50 ページ 2012年7月26日 木曜日 午後6時4分